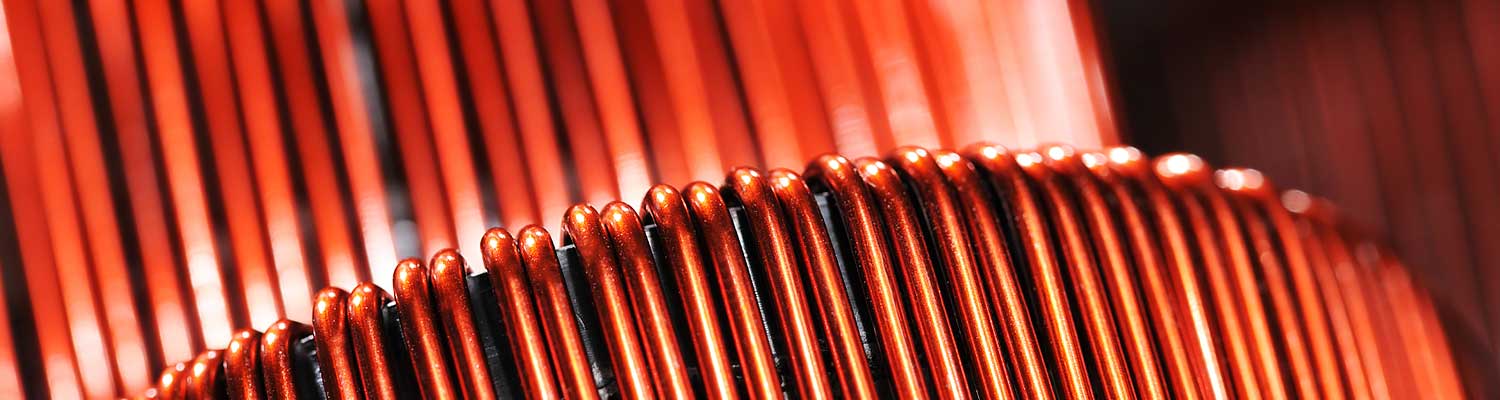

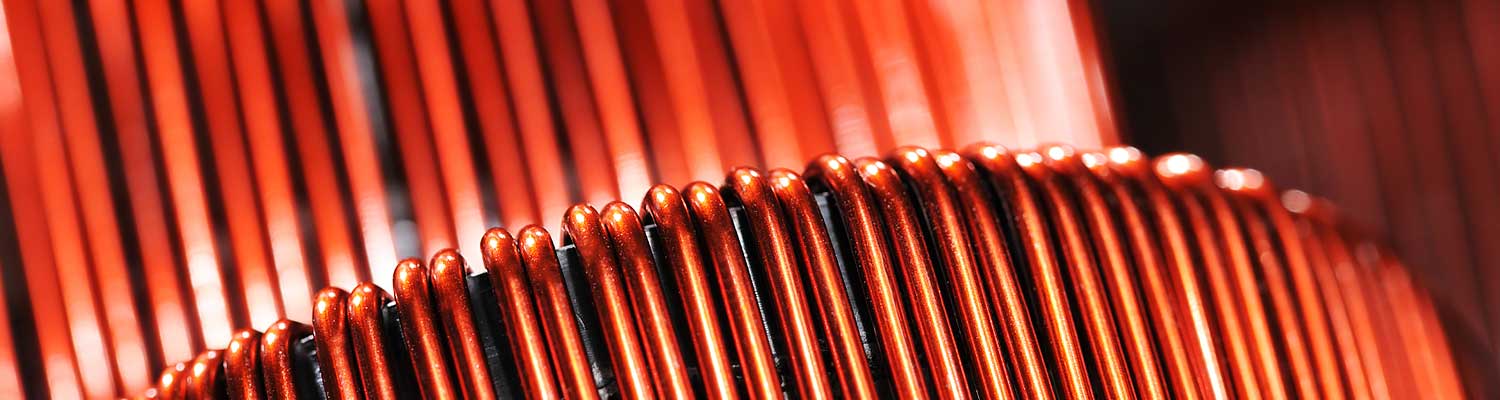

A coil is a wire that is wound in a spiral. This simple component is used in equipment to filter or select signals of a specific frequency. The wires in a coil can be wound around a core, often in the form of a bar or a ring, but there are also what are known as air-wound coils, which are often wound on a bobbin in a winding machine. When the coil is wound, it is removed from the bobbin. If the application requires a more stable coil, it may be advisable to use a plastic-coated copper wire which, after winding, is heat treated in a furnace causing the plastic to melt and hold the coil together.

Typical applications for coils are:

An inductor transmits direct current, but more or less blocks alternating current, i.e. put simply an inductor has the opposite effect to a capacitor. Inductors are used in tuning and resonance circuits (filters).

When the current through a coil increases, the magnetic field around the conductor also increases. If you reduce the current, the magnetic field also reduces, and the energy is returned to the electric circuit.

We can supply all types of wound coils including the accompanying bobbin frame. The coils can be supplied with or without connector pins in the bobbin. The ends are either laser welded or soldered on. Nor are Litz wire and large volumes a problem. Contact us for a consultation.

With wire diameters down to 12 μm we can supply both small and large air-wound coils in all types of shapes. Everything from simple round coils to complicated geometries with the associated development work.

A further refinement that we can offer is the moulding of coils. The entire coil is finish manufactured with its winding and contact system to be moulded in a plastic casing at the final stage. Contact us for a consultation.