We develop, produce and deliver profitable & sustainable products & sub-systems.

We are not a design consulting company that has the goals to sell billable hours. Instead we are an elite design team helping customers through the whole process from idea to a ready-made serial produced product. Self-developed by us or in collaboration with our clients.

Create a low-risk and high-reward scenario. We do not take large pre-studies fees or long-term payment. Instead, we use our skateboard model to breakdown a project down in small pieces where we can complete and deliver value every step of the way.

Depending on your challenge – our mission is to contribute the parts of your vision.

We complement research & develoment processes and elevate products. Our fields of expertise combine cutting-edge expertise in several areas.

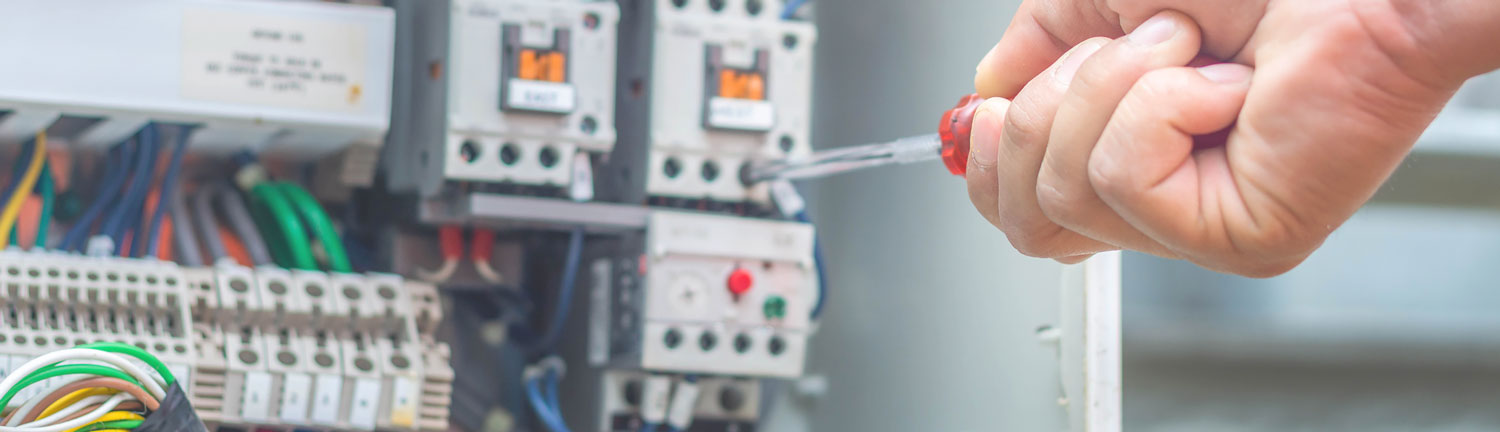

Electrical

ElectricalExperienced designers with electrician experience to make final product right on first iteration.

Electronic

ElectronicReady to use modules from in-house design resource library which shorten time-to-market.

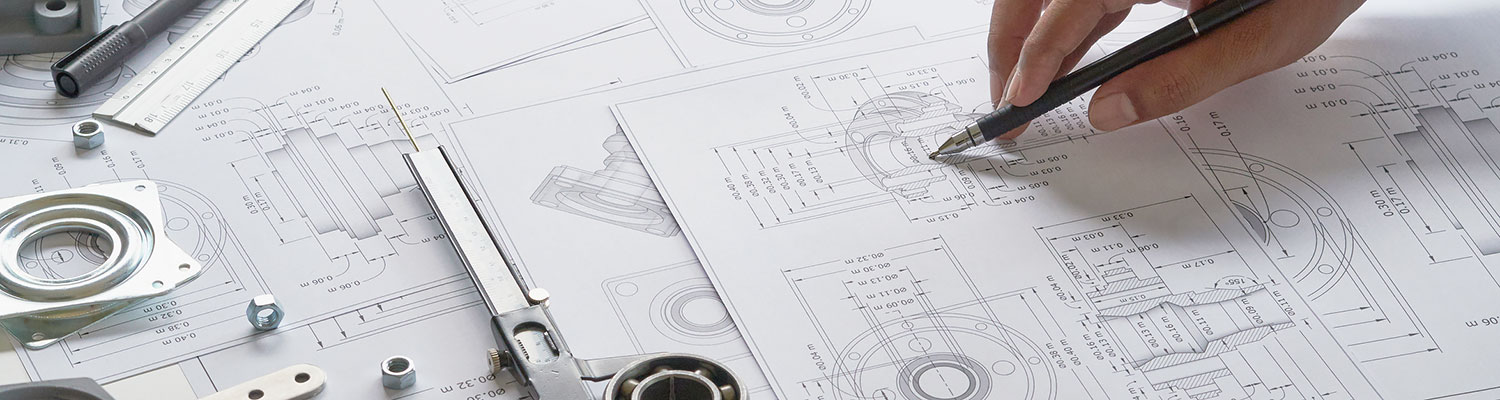

Mechanical

MechanicalExpertise in structural analysis and transfer of mechanical energy in the most efficient fashion.

Software

SoftwareStrong focus on reliable and tested code snippets to complement the whole application.

Our project method allow us to deliver consistent result when transfering ideas quickly, safely and efficiently into optimised serial productions.

Research

ResearchWe collaborate with users and stakeholders to understand their workflows and needs.

Ideating & Sketching

Ideating & SketchingPopulating ideas is the key to discover new solutions.

Prototyping

PrototypingTesting ideas through prototypes with users helps us to eliminate less feasible and non-ergonomic solutions.

Realization

RealizationFrom ideas to manufacturable solution is a result of a long lasting partnership with our customers.

DFM

DFMOptimizing products at the DFM stage could be already too late. Having DFM experts in the team saves time and money.

For more than 30 years we have developed everything from simple solutions to pioneering advances for optimum levels of engineering precision and efficiency. Now we complement with our own engineering and industrial design. One stop shop with turnkey solutions - that make your vision a reality.

Electronic Design

Electronic Design Industrial Design

Industrial DesignWith our long experience and unique combination knowledge in product design, supply, and manufacturing, we can take a product or process and optimize parameters such as cost, performance, and quality to meet today’s market specific needs.

A small change can be a big difference to increase profitability or take over new market shares. Our optimization service is a unique service that we offer to our customers

Our experienced application engineers work daily to develop unique products for our customers. For example, we have produced printed circuit board design, developed strategic branding and product segmentation for our Xynrgi product line. When you turn to us, the final result is worth more than the sum of its components, regardless of whether the task is to develop a product, help you with industrial design or both.

The client wanted to buy a drive and a motor. We went in to ask a bit more what they wanted to do. Assisted them in the design of the panel. We did the design for a consulting rate and had the chance to integrate our products in their design.

Doing the design on Zuken E3.

Building a prototyp and sent to use for test.

Preparing all documentation for full scale production.

Providing a education to prepare the customers team in how to build this cabinet themselves.

The client wanted a motor and was asking about if we could redo their motor driver which had some issues. We instead made a PCB that will fit in the motor case which will save the costs of manufacturing, cabling and installation.

Steps through the process:

Building a quick prototype.

Designing with Altium Designer, written software on MPLAB for microchip.

Producing a small scale of 10 pieces for testing.

Simulation of long term testing for 500.000 cycles.

Running a pre-compliance test with ESD discharge test.

Providing all documentation for full scale production.

Doing the production, programming and testing through EMS.

The client had a hand control which was popular but wanted to decrease the cost of production while adding new value to the end-customer with better ergonomics. In this case we were able to adjust the costs, performance and quality of the product which allowed the client to increase margins and take over new market shares.

1. Initial workshop with design team to look over the product and construction.

2. Issued a list of possible features and ergonomics adjustments.

3. Proposed a series of possibilities to choose from.

4. First prototype for test fitting and testing of new structure.

5. Final design, with DFM and renders.

Don´t hesitate to contact our developers if you want to know how our resources in electronics, electrical, mechanical engineering and industrial design can help your vision for your next application become reality.

Contact our developers