Many compact designs require a motor with a vast amount of power in a small package. With standard solid shaft motor, it can sometimes be a real challenge to fit all components within the boundaries of the design while also having enough torque available.

Hollow shaft motors overcome these technological limitations by providing high torque while also keeping weight to a minimum and allowing fluid or mechanical components to be guided through the central cavity of the motor. This can include components such an external shaft, cables or a fluid used as a heat exchanger to effectively reduce heat development in the motor and neighbouring components.

RoboDrive´s hollow shaft motors’ provide high torque output and low weight, they are ideal for industries such as medical, aerospace, robotics and automation. However, due to the opportunities these motors provide for innovative designs, their application areas are far reaching.The high-torque hollow shaft Brushless DC motors provides one of the highest torque to weight ratios on the market in addition to exhibiting excellent dynamics, reliability and precision.

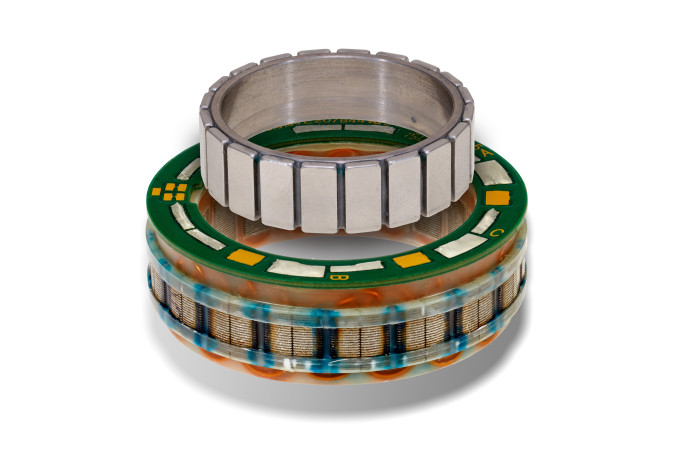

The Servo-Kits allows for further space minimisation while keeping the high performance by allowing for integration of the core components of a motor straight into your design. The Servo-kits, which consists of a rotor and a stator, can also be fitted with an integrated, high-resolution absolute encoder. When an even higher torque is required, we offer a hollow shaft gear motor solution. These motors allow for a peak output torque of up to 176Nm while only being the size of a coffee mug.

For many industrial applications, engineers have resorted to available drive motors without optimizing these for the respective application. For many mechatronic drives, such as the axle drives of robots, however, careful selection is a prerequisite to achieve the maximum torque and precision at a minimum weight and minimal power loss.

A majority of all the products we supply are customised or specially developed for a specific application. With our extensive R&D facilities behind us, we are keen to be involved from the concept stage in order to adapt or develop the product and optimise it to meet your challenges. Read more about how we create value.

Optimized motor components that is built into your application in order to create your own motor.

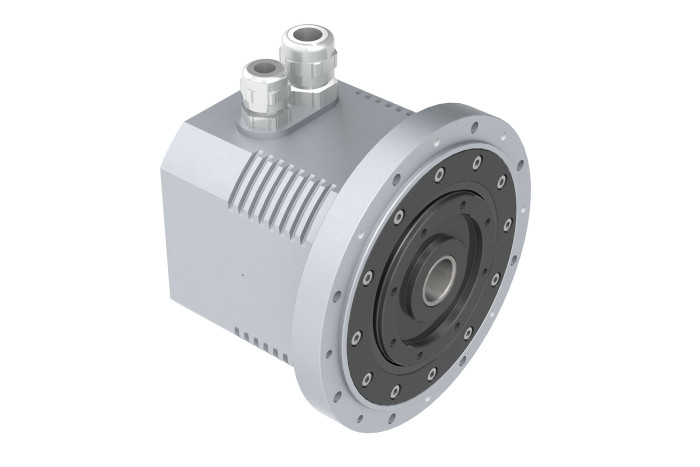

The motor-gear unit ILM-PG offers a standardized drive solution in combination with Neugart’s powerful planetary gears. Depending on the number of stages, transmission are covers ratios from 1:3up to 1:512. The gears offer a minimal backlash. The units are highly robust and have a lifetime lubrication. All performance characteristics of the gear in speed and torque are achieved in the combination with RoboDrive technology. Combinations of RoboDrive motors and Neugart gears can be tailored to given requirements. It is also possible to use the Neugart precision gears and flange gear boxes.

With a peak performance of up to 5200 W in a built-in-space of 165x165x130 mm and a hollow shaft of 50 mm, the ILM115x50-IMD is the strongest motor with a market leading power density. Due to the design, with three independent windings, it is possible to operate this device with three synchronously running compact servodrives at max. 50 A per winding.

The geared motors of the RD-HD series are powerful and high-precision servo solution with hollow shaft for low-voltage applications. The technology from Harmonic Drive uniquely combines highest precision and zero backlash in a compact lightweight design. Combined with our RoboDrive technology, the harmonic drive can be exploited to the peak load. Due to the outstanding dynamics of this motor and the very low gear elasticity and inertia it is possible to precisely control the powertrain. The geared motors RD-HD are successfully used in robotics, handling and automation, medical and optical applications.

Complete motors with a conventional, solid output shaft that gives you a short time-to-market.ort time-to-market.