Hand tools place demanding requirements on the component parts. They have to be light, impact resistant and must not get too hot. In addition, they must withstand rough treatment, which often means knocks and bumps, still without affecting their functioning. We have set out a few of our products that we consider particularly suited to research or technical training below. We’re sure to have missed something, or you may know of something that we haven’t thought about. Please regard it as a form of inspiration rather than as an indication of the products we have for your application.

High-performance servo motor with Hall-effect sensors and/or encoders. The motor has a 4-pole rotor which provides a higher torque at a lower speed, which in turn means a lower gear ratio, more compact dimensions and a higher efficiency. Available in four sizes ranging from 22 to 32 mm in diameter. Completely free of magnetic cogging.

Cage-wound servo motors ranging from 6 mm diameter to 44 mm in diameter for demanding applications. Available with a variety of different gears and feedback, including encoders and analogue and digital Hall-effect sensors. Highly efficient cage-wound design providing high torque in a compact format and low weight. Highly dynamic acceleration and deceleration. Completely free of magnetic cogging (also referred to as magnetic detents).

The robust planetary gears in this range are designed for installation with Faulhaber precision motors for applications requiring high torque and high performance. Available in a range of different designs made of plastic or metal with sintered or ceramic bearings or ball bearings. There are also modified versions for high temperatures or other demanding environments.

This range of motors takes linear motion to completely new levels. These miniaturised and high-performance linear motors consist of a solid stator with self-supporting winding and a multi-pole magnetic bar. Highly efficient magnets help the motors to achieve an excellent dynamic performance and power.

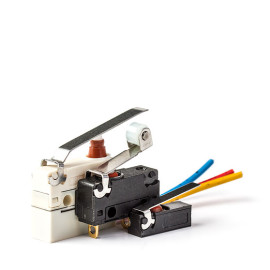

A microswitch is a type of selector switch for installation in specific industrial applications and equipment. They break currents that are large in relation to their size and they are used virtually everywhere where there are high requirements for performance in relation to safety, accuracy and precision.

In almost all cases a magnet will be combined with iron to increase the performance. We call this a magnetic system and we can supply both magnet rotors, magnetic couplings and magnetic holding systems with the associated magnetic calculation consultation.

Low frequency magnetic fields have a disruptive effect in many different situations. We can offer solutions to many problems with interference with our ready-made magnetic shielding which can be specifically tailored to every conceivable situation such as magnetically shielded rooms and shielding for automotive applications.