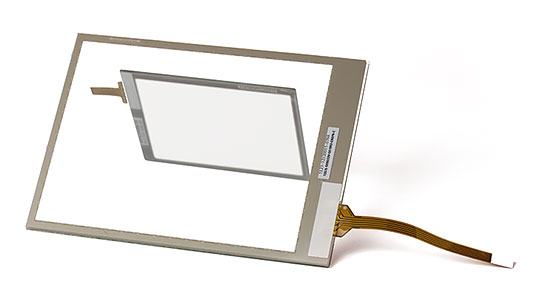

Touch panels are combined with screens to produce touch screens. Previously, resistive panels were most common but in recent years capacitive touch panels have gained a lot of ground. These resistive panels are based on two parallel layers separated by an air gap. When the user presses the outer layer it comes into contact with the inner layer and can therefore register where the user is pressing.

The capacitive touch panels are based on conductive material affecting the capacitance of the sensor surface. For example, a finger is to some extent conductive and therefore affects the capacitance so that the location of the finger on the surface can be registered. Capacitive panels often have a lower resolution than resistive ones, but have other advantages such as multi-touch capability, i.e. the ability to register several touch points at the same time.

Touch panels are used to advantage when interactive products are to be developed. We also offer control and drive electronics for various types of touch panels, displays and pushbuttons.

A variant of capacitive touch in which the touch screen consists of a sheet of glass which is coated with rows and columns of a conductive material in several layers. When a conductive object such as a finger approaches or touches the sheet of glass a change in capacitance can be registered at this point and thus tracks where the user is touching. This capacitive touch also supports several simultaneous touches. The technology is more robust than resistive touch since there is a sheet of glass protecting against dirt and scratches. If gloves are used, these should be thin in order for the touch screen to work well. The disadvantage with capacitive touch is that complicated coding is required and moisture can disrupt the system.

The great advantage of resistive touch screens is their simple operation, the mechanical compression of a plastic film against a sheet of glass, both of which have a surface layer of conductive material which come into contact, and the touch position is calculated by voltage division. All the required items for generating contact can be used with this technology.

Four-wire touch

Resistive touch panels based on four wires are the most economical technology and the one that is most common in the choice of touch screen.

Five-wire touch, affordable and durable high performance resistive touch

Resistive touch panels with extra high performance and resistance as accessories for TFT and LCD which are exposed to scratches and pressure. These five-wire touch panels withstand being boiled in water without affecting their performance. The temperature range in operation is from -30 to +85°C and from -40 to +85°C in storage, which can be compared with normal four-wire touch panels that only withstand operation down to -20°C. The extra resistance makes them an interesting alternative in some cases to the highly durable capacitive touch panels which are more complicated to operate and have a comparatively higher price.

A further option is for the five-wire resistive touch panels to be available in versions with thin micro glass 0.1-0.2 mm thick providing a more durable, more easily cleaned surface.

SAW stands for Surface Acoustic Wave and is based on the principle that a standing wave in the ultrasonic spectrum passes across the panel. When the panel is touched, part of the ultrasonic wave is absorbed, thus registering where the touch panel has been touched.

Infrared touch is based on registering where the light waves have been disrupted to detect where the touch screen has been touched. They have the advantage that they work with gloves for example and are therefore suitable for outside environments.