Maximum torque and high precision – at the lowest possible weight and power loss

Innovative hollow-shaft motors for applications that require i.e. pneumatics or electrical wires to be routed through the center of the motor.

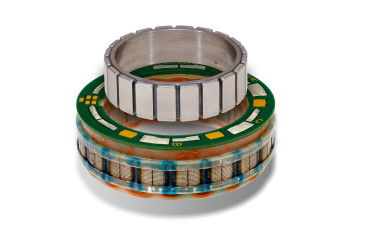

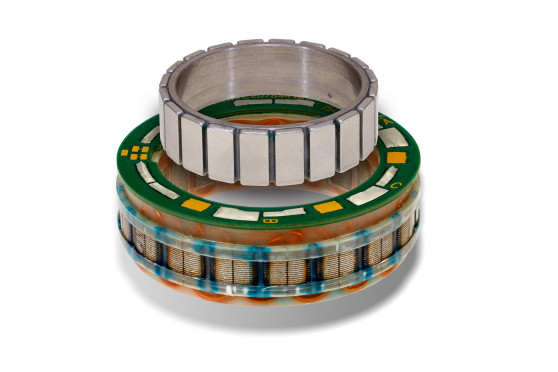

Optimized motor components that is built into your application in order to create your own motor.

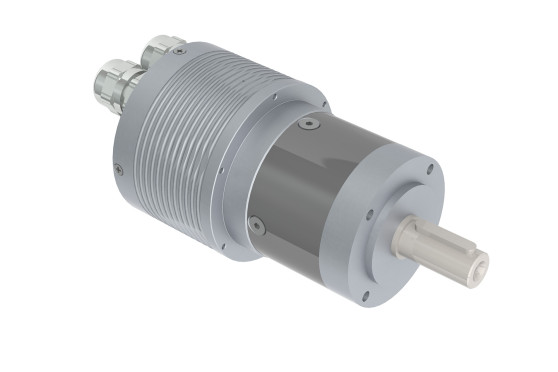

Complete motors with a conventional, solid output shaft that gives you a short time-to-market.

For many industrial applications, engineers have resorted to available drive motors without optimizing these for the respective application. For many mechatronic drives, such as the axle drives of robots, however, careful selection is a prerequisite to achieve the maximum torque and precision at a minimum weight and minimal power loss. By optimizing all relevant motor parameters while observing the required load profile (concurrent engineering), the researchers at the Institute of Robotics and Mechatronics at the German Aerospace Center (DLR) were able to develop the new “RoboDrive” motor technology. This technology combines high torque development and power density in relation to weight and size. Dimensions such as synchronization, dynamics and thermal connection are aligned to the particularly high demands of robotics. The RoboDrive motors have been manufactured by TQ Systems since 2006. The product spectrum includes standard stators and rotor sleeves as installation sets for the highest possible user-specific integration. Alternatively, the motors can be equipped with hall sensors or magneto-resistive position sensors, depending on the application and requirement profile for speed or motion detection.

The motor-gear unit ILM-PG offers a standardized drive solution in combination with Neugart’s powerful planetary gears. Depending on the number of stages, we can cover transmission ratios from 1:3up to 1:512. The gears offer a minimal backlash. The units are highly robust and have a lifetime lubrication. All performance characteristics of the gear in speed and torque are achieved in the combination with RoboDrive technology. Combinations of RoboDrive motors and Neugart gears can be tailored to given requirements. It is also possible to use the Neugart precision gears and flange gear boxes.

We are entering a new dimension in terms of compact drive units with our new motor concept. With a peak performance of up to 5200 W in a built-in-space of 165x165x130 mm and a hollow shaft of 50 mm, the ILM115x50-IMD is our strongest motor with a market leading power density. Due to the design of our motor with three independent windings it is possible to operate this device with three synchronously running compact servodrives at max. 50 A per winding.

The geared motors of the RD-HD series are powerful and high-precision servo solution with hollow shaft for low-voltage applications. The technology from Harmonic Drive uniquely combines highest precision and zero backlash in a compact lightweight design. Combined with our RoboDrive technology, the harmonic drive can be exploited to the peak load. Due to the outstanding dynamics of this motor and the very low gear elasticity and inertia it is possible to precisely control the powertrain. The geared motors RD-HD are successfully used in robotics, handling and automation, medical and optical applications.

On request other sizes and types of Harmonic Drive gears are delivered with matching motors.