A DC motor is an electric motor with a relatively simple design with high levels of reliability and high dynamics providing good efficiency. The commutation takes place mechanically by means of brushes made of graphite or precious metals. DC motors are found in a wide range of different applications – everything from fairly simple models used in toys, vacuum cleaners, electric toothbrushes and electric windscreen wipers to high-performance models for use as servo motors or compact drive units for applications in medical technology, optics, handling robots, electric hand tools or metrology and analysis equipment.

A DC motor is often combined with a gear unit to reduce the speed and increase the torque. For servo applications the motors are usually combined with some type of position feedback, usually pulse encoders.

In addition to having one of the best selections on the market for anyone looking for a DC motor, we also provide the option of creating a completely unique motion solution based on DC motors. This is regardless of whether this is a fairly simply motor or a more advanced servo motor.

It is not always obvious which type of motor is best suited to each application. The traditional DC motor has a coil which is wound round an iron core. This is a reliable, simple and cost-effective design that provides a relatively good service life. They are ideal where there are no particular space limitations and where no battery operation requires the motor to have as high an efficiency as possible and as low a weight as possible.

A motor with a self supporting rotor, (also referred to as an ironless, coreless or cage-wound motor), has a much lighter rotor which also generally has a lower overall weight, higher efficiency and higher power density. This type of motor is ideal when space is limited or when battery time and weight are critical factors.

A majority of all the products we supply are customised or specially developed for a specific application. With our extensive R&D facilities behind us, we are keen to be involved from the concept stage in order to adapt or develop the product and optimise it to meet your challenges. Read more about how we create value.

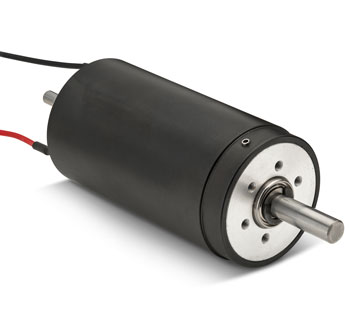

Small DC motors in this series, are based on the cage-wound, coreless and self-supporting windings. Combined with a gear unit and feedback (encoders or Hall-effect sensors) they are very potent servo motors for applications requiring maximum dynamics and high power in as light and compact a form as possible. The characteristics are a cogging free movement, high torque, low weight, low moment of inertia, dynamic operation and low torque ripple.

Traditional, powerful and compact motors ranging up to 500W. These motors are based on the cage-wound, coreless and self-supporting windings. Combined with a gear unit and feedback (encoders or Hall-effect sensors) they are very potent servo motors. The characteristics are low mechanical loss, high power conversation effeciency and relatively energy saving.

Hall sensors and gearboxes, integrated with DC motors. Optimal sensor or encoder technology – tailored for your specific application requirements – ensure your motors respond precisely to command from the drive electronics

DC motors with integrated gearboxes are used to optimize the balance between speed and torque to suit specific application requirements. The gearbox also enables the system to handle greater axial loads, enhancing overall performance and durability.