Encoders

Looking for a reliable encoder? We have a wide range of encoders based on different technologies, each with it’s own advantages. An encoder is typically used either as a speed sensor or as a position sensor and is often found in a range of servo applications, such as robotics or automation.

Optical encoders

For over 20 years, Celera Motion’s MicroE innovative and patented PurePrecision™ technology has been the core optical technology platform to deliver precision optical encoders to the market that are significantly smaller and easier to align and install than competitive products. This technology has enabled designers of precision motion control systems in medical, robotic, semiconductor, advanced industrial and scientific applications to design smaller, lighter and more energy efficient machines and instruments.

Inductive encoders

Celera Motion’s Zettlex position sensor technology uses a unique inductive technique. The basic position sensing principles are similar to traditional inductive proximity switches or measuring transformers but rather than wire windings or spools, Celera Motion’s inductive encoders use printed circuit boards (PCBs).

Advantages of Celera Motion’s inductive encoder technology include:

- High accuracy

- Stability irrespective of environmental conditions

- Measurement performance largely independent of installation tolerances

- Insensitivity to foreign matter

- Compact size

- Lightweight

- Ability to sense over a wide range of geometries

- No need for bearings, bushes or seals

- Can also be used to measure weight, vibration, strain, shock, tilt, pressure and even temperature (by expansion).

GUIDE: Common problems with encoders

Encoders are providing critical feedback to motors for position, speed, and direction control. However, like any mechanical or electrical device, encoders can sometimes encounter problems that disrupt system performance. In this guide we’ll explore some of the most common problems offer troubleshooting tips to help you diagnose and fix them.

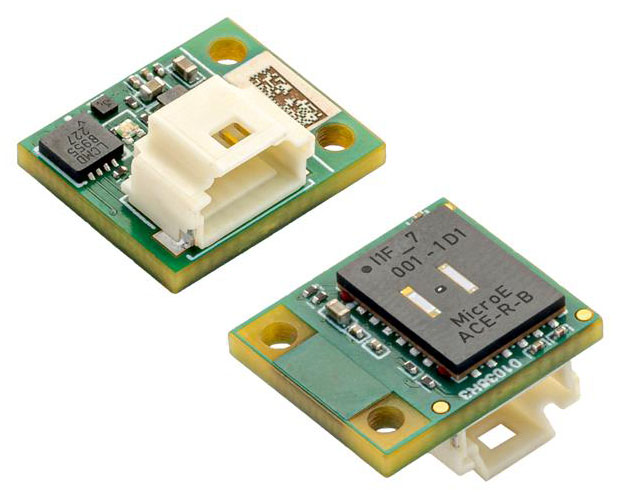

Celera Motions Aura™ absolute optical encoder

Minimal encoder measuring 9.0 x 7.0 x 1.2 mm for PCB surface mounting. The resolution is up to 22 bits (4194304 steps), accuracy of ±0.01° and repeatability of ± 1LSB. These properties make Aura™ well suited for advanced robotics in medical technology, near-body technology and pick-and-place machines for the manufacture of, for example, semiconductor components.

Celera Motion’s MicroE optical encoders

Celera Motion’s MicroE products are built with PurePrecision™ and VeraPath™ technologies. The miniature precision optical encoders is available in several form factors and mounting options, with incremental and absolute interfaces and resolutions up to 1.2 nm. A wide selection of rotary and linear scales are available, delivering accuracy up to 1xm.

The range is comprized of

- Rotary encoders

- Linear encoders

- Tape & glass scales

- OEM encoder solutions

See the full Celera Motion optical encoder product range

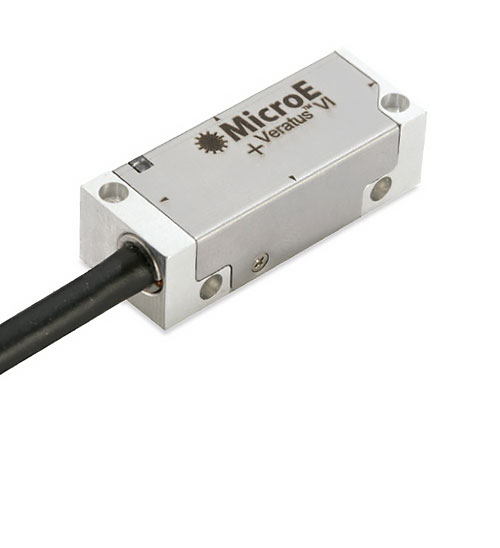

Celera Motion’s Zettlex inductive encoders

Robust Angular Position Measurement for Extreme Environments. Celera Motion’s position sensors use non-contact, inductive technology. Rather than the bulky transformers of traditional inductive sensors, Celera Motion’s Zettlex sensors use printed circuits. This enables compact, accurate, lightweight and robust position sensors with no contacts, no delicate parts, no maintenance, no hassle – just accurate measurements – all day, everyday.

See the full Celera Motion inductive encoder product range

DC- and BLDC-motors with integrated encoders

Hall sensors, optical- or inductive encoders integrated with our DC- and BLDC-motors. Optimal sensor or encoder technologies tailored to your spcific application requirements.

Classical encoders

Designed for standard shafts and deliver exceptional performance, whether incremental or absolute. Full control over design, electronics, and production, allowing us to tailor solutions for any application, even low-volume orders. From custom cables and connectors to seamless integration with your motor or system, our encoders save time, reduce maintenance, and ensure optimal performance. Whether replacing a legacy encoder or creating a new system, we deliver precision-engineered solutions that meet your exact needs.