Almost all types of motors require some form of motor controller in order to be used efficiently and safetly. In some cases this may be something as simple as a manual on/off button, but in most cases something a little more sophisticated is required. Regardless of whether the objective is to maintain a smooth speed irrespective of load or to make a circular interpolation between two axes, we have a motion controller to suit your requirements.

Motor controllers are often divided into two categories: drivers and controllers. The task of the driver is to provide the motor with current whereas the task of the controller is to calculate how much current the driver must deliver to the motor. Put simply, you can therefore regard the driver as the muscles and the controller as the brain. It is not unusual for the products to be combined, i.e. a driver with an integrated controller.

For many years different types of bus system have been common in motor controllers. We work with the most common ones: Ethernet, CANopen and EtherCAT. Ethernet and CAN are proven and reliable systems that have been used for many years. EtherCAT is an industrialised Ethernet-based fieldbus system, which provides significant advantages over CAN, mainly in relation to transmission speeds and time synchronisation.

FAULHABER, Galil and Ingenia (Celera Motion) each have their own development environment for developing application software, carrying out servo tuning etc. Further information about each manufacturer’s development environment is available under the Software link.

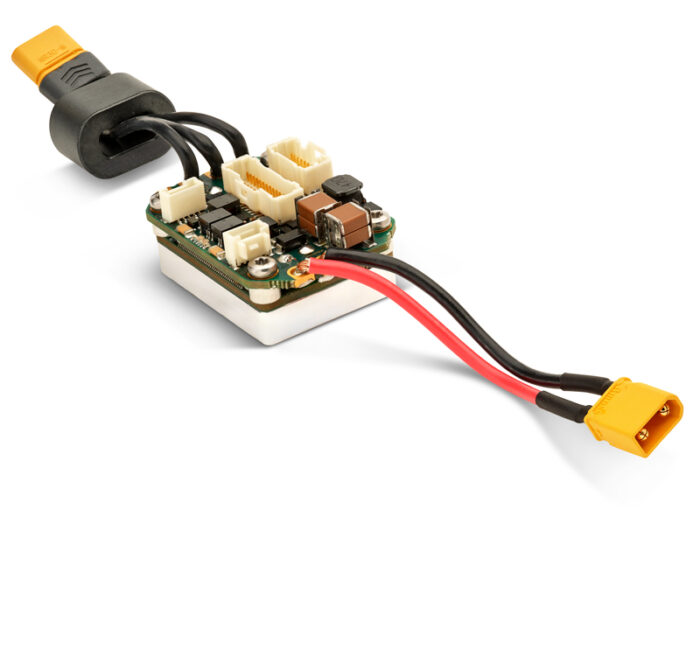

Need more features than just motion control on your board, or want to break out your motion control module to a specific set of connectors? We can help you design, test, verify and produce a custom PCBA to fit you application’s specific needs. Just let us know what you need to achieve.

When an external force is applied to a system, standard PID parameters may not be sufficient to compensate for it. To better understand how to address this problem, four applications with external forces will be analyzed and an effective solution will be provided for each application. These applications include servo motors moving a vertical load, a spring load, a lever arm, and a compressible substance.

By designing a streamlined version of a complex drive, we can help you achieve both cost savings and space efficiency without compromising on performance.

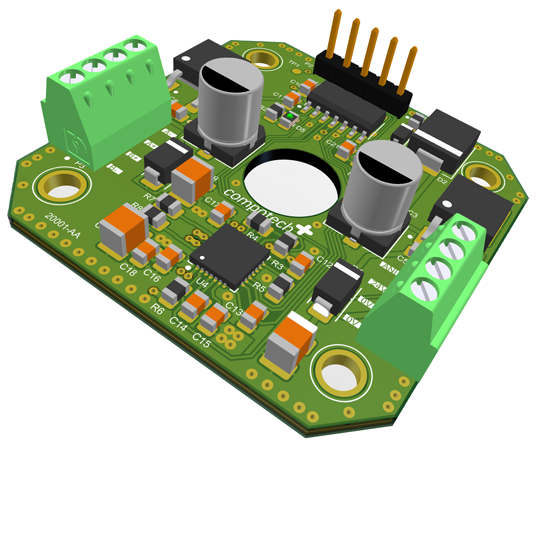

The DMC series comprises advanced controllers for 1-8 servo or stepper motor shafts, which can also be combined with built-in drivers. With leading servo performance, powerful software tools and a shallow learning curve this is an excellent choice for centralised servo systems with high requirements for performance, advanced functionality and user-friendliness.