The brushless motors (also referred to as EC motor or BLDC motor) is a further development of the traditional DC motor. In simplified form it can be regarded as a DC motor that has been turned inside out, in which the magnet is rotated and the copper winding remains stationary. The advantage is that graphite or precious metal brushes are not required to transfer current to the windings. In this way the factor that is most limiting in terms of the motor’s service life has been removed. In many cases the service life of a brushless motor is many times more than that of an equivalent DC motor.

Instead, some type of feedback needs to be added to make the motor rotate. This is often achieved by Hall-effect sensors, which detect transitions between magnetic poles, and can therefore be used to indicate the position of the rotor (magnet) in relation to the windings.

The characteristics of brushless motors or EC (electronically commutated) motors are a long service life and high efficiency.

Brushless motors are used in a wide range of applications. Fairly simple models are used for conveyor belts and in heating/ventilation whereas high-performance models such as cage-wound motors are used where performance, precision and above all torque are important, for example in robotics or medical technology.

In many cases brushless motors are combined with Hall-effect sensors and/or pulse sensors (which we normally refer to as servo motors) and some type of gear to reduce the speed and increase the torque. Gear units such as worm gears or planetary gears are used depending on the application. The brushless motor also needs a motion controller or a driver to work.

We have a wide variety of brushless motors in our standard range, but if we are still unable to find a standard motor suitable for your application, we will be pleased to help by customising a motor so that it fits like a glove.

A majority of all the products we supply are customised or specially developed for a specific application. With our extensive R&D facilities behind us, we are keen to be involved from the concept stage in order to adapt or develop the product and optimise it to meet your challenges. Read more about how we create value.

Coreless servo motors ranging from 10 mm diameter to 42 mm in diameter for demanding applications. Available with a variety of different gears and feedback, including encoders and Hall-effect sensors.

Highly efficient coreless design providing high torque in a compact format and low weight. Highly dynamic acceleration and deceleration enables speeds up to 51,300 rpm. Completely free of magnetic cogging.

High-performance servo motor with Hall-effect sensors. The motor has a 4-pole rotor which provides a higher torque – up to 180 mNm at a lower speed, which in turn means a lower gear ratio, more compact dimensions and a higher efficiency. The innovative rotor winding minimizes losses and enables speeds up to 8100 rpm. The motors ranging from 28 to 42 mm in diameter and are completely free of magnetic cogging.

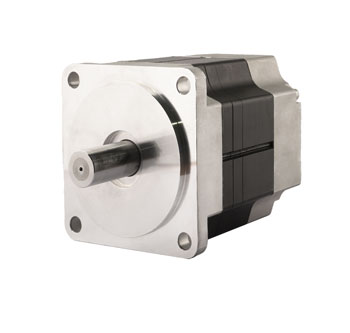

Brushless DC-motors in 6 different sizes ranging from 42mm to 130mm have several advantages including start and speed regulation, high power density and over load capacity. Rated torque from 0,0625 to 6,7 Nm and efficient low speed ranging from 1000 to 3000 rpm.

A wide range of truly miniaturised motors, with the accompanying gears, electronics and linear components. These motors offer a long service life and high dynamic performance in addition to compact dimensions and are completely free of magnetic cogging.

The motor range comprises for the highest possible user-specific integration. Available in a wide variety of different technologies as accurate arc-shaped motion profiles and slotless motor techology.