This category contains the only “digital” motors that make movements in discrete steps. We deliver both permanent magnet motors and hybrid stepper motors in a wide range of designs. The motors are highly reliable, have a long service life, a relatively low price and deliver a high torque, compared with DC motors, for example. As a trade off you get a relatively low efficiency, which can result in high temperatures. This low efficiency also means that you should think twice if you are considering using stepper motors in battery-powered applications.

Stepper motors are found in a wide range of applications where price and torque are most important, such as office equipment, printers and heat exchangers, but due to the unique characteristics of the motor it may also be suitable in high-precision applications in medicine, robotics and automation.

Stepper motors supply a relatively high torque and manageable speeds so a gear unit is seldom required, but it may be justified in some applications. Stepper motors are excellent for use for positioning where the design means that it is possible under normal conditions to keep track of where you are, but that under certain circumstances you can lose track and therefore find yourself in a different position from the one you should be in. To rectify this stepper motors are sometimes combined with an encoder to help the motion controller to correct the position where necessary.

Stepper motors often comply with a generally accepted standard in terms of mounting holes, pilots etc, but the windings vary a great deal between different manufacturers. We will be pleased to help develop a motor with a winding optimised for your application. If you need to make mechanical changes as well, there are plenty of opportunities to do this.

When an external force is applied to a system, standard PID parameters may not be sufficient to compensate for it. To better understand how to address this problem, four applications with external forces will be analyzed and an effective solution will be provided for each application. These applications include servo motors moving a vertical load, a spring load, a lever arm, and a compressible substance.

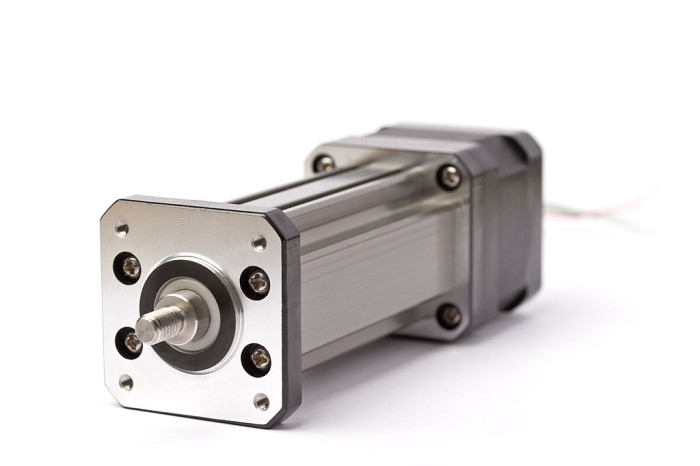

Stepper motor-driven complete linear units & rail guidance. Our partner Dings Motions’ further development of stepper motors with lead screws – saves design time and assembly. The stroke length of the linear units ranges from 20mm (NEMA 6) up to 600mm (NEMA 23). The thrust force ranges between 15N and 910N depending on the NEMA size chosen.

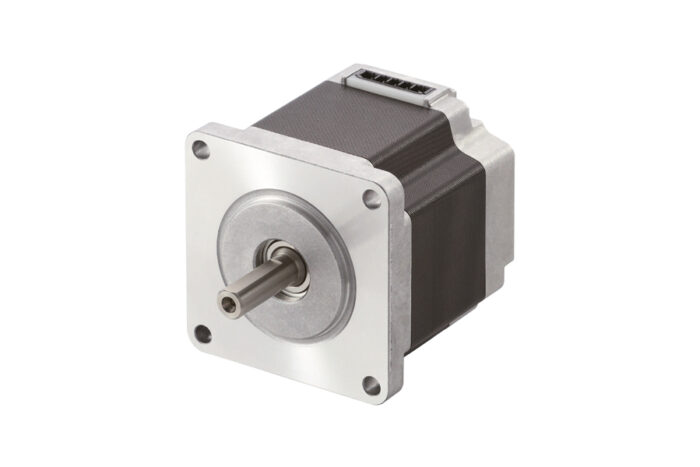

NEMA-standard stepper motors in a variety of different sizes ranging from 20 mm square (NEMA 8) to 110 mm square (NEMA 42). Hybrid stepper motors are built for a long service life and high torque. Choose from several different windings, both two-phase and three-phase.

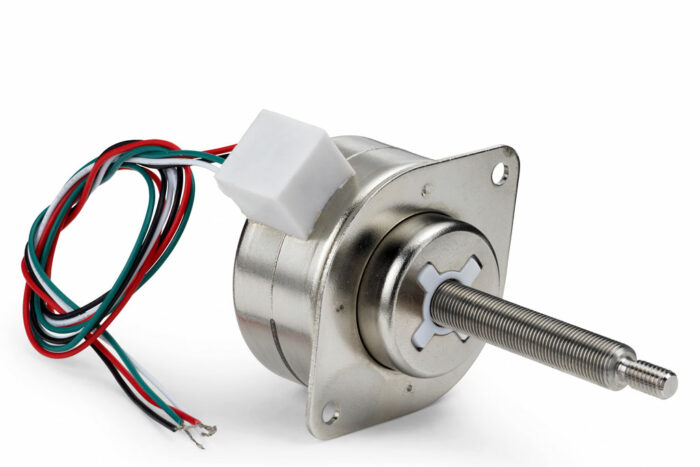

Stepper motors in which the shaft is either a lead screw with nut or in which the rotor is a nut with a transverse lead screw. When the nut or screw (depending on the model) is prevented from rotating, a linear motion is obtained. Available with various windings and in sizes ranging from 14 mm to 86 mm square. Produces up to 2270 N. The lead screw can be coated with Teflon for lower friction on request. This type of motor also provides a number of options for customisation. Read more about linear motors here.

A fully finished actuator based on a stepper motor in sizes ranging from 20 mm to 60 mm square. The actuator can deliver just under 1050 N continuously depending on the model and pitch.

A hollow shaft motor where the front part of the screw is prevented from rotating, instead the shaft moves at the back of the motor.

Stepper motors with a wide range of speeds and exceptional performance that are also suitable for very demanding environments. The series, which ranges from 6 mm to 22 mm in diameter, can be combined with a number of modular servo elements such as encoders, backlash-free gears, integrated lead screws and much more.

Hybrid stepper motors combined with drivers and controllers from Oriental Motors or Lin Engineering. Available in sizes ranging from 42 mm and 86 mm for either AC or DC supply. Also motors in which the control electronics are integrated into the motor housing in sizes ranging from 42 mm to 86 mm.

Highly compact hybrid stepper motors with dimensions of 42 mm square and only 14 mm or 17.8 mm long (excluding shaft). Ideally suited to applications with limited space and that require a high speed.

Although our standard motors are robust and reliable, some applications require slightly more than the standard protection. The IP65-classified stepper motors are fully protected against dust and withstand low pressure water jets. In addition, the surface coating of this range of motors is food grade. Available sizes ranging from 42 mm to 86 mm.

Although our standard motors are robust and reliable, some applications require slightly more than the standard protection. These vacuum-classified stepper motors are manufactured to meet clean room requirements in which outgassing cannot be permitted. Motors in this range are not painted and contain no oil. Sizes ranging from 20 mm to 57 mm.