Do complete linear units fit in your application?

Congratulations, you can then significantly simplify the design work. With stepper motor-driven complete linear units & guides, the support already done, you just need to mount your load.

Our partner Dings Motions’ further development of stepper motors with lead screws – takes you one step closer to a finished product. All you need to do is mount the load, the rest is already done. But before we get that far, we need to decide on the efficiency, precision, speed, stroke length, and force required. This affects the length and pitch of the lead screw and whether it should be supplemented with an encoder. All this influences the choice of motor size. When it comes to which of the DSM or DLM series is best suited, it depends on the available space and how much time you want to save in terms of assembly.

Which size is best?

Which of the NEMA sizes 6, 8, 11, 14, 17, or 23 does the job in your application depends on how quickly, heavily, and far you need to move your load. The stroke length of the linear units ranges from 20mm (NEMA 6) up to 600mm (NEMA 23). The thrust force ranges between 15N and 910N depending on the chosen NEMA size.

There are two types of complete linear units, DSM and DLM

In short, DLM and DSM differ in that the rail in DLM is permanently mounted on an aluminum base while in DSM, the rail requires assembly against a suitable surface. This means that DLM is more ready to use, and the unit can basically be standalone. The rail not being permanently mounted makes DSM more space-saving while some assembly time is saved with DLM.

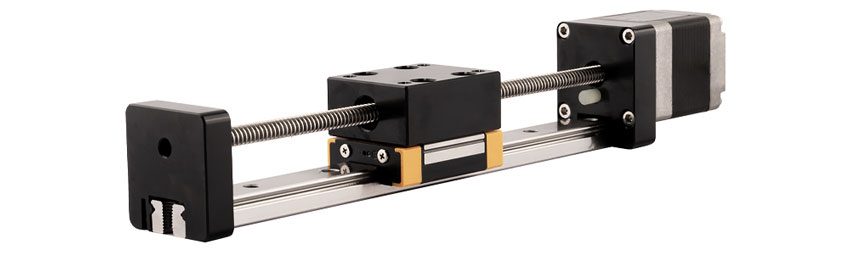

DSM – DINGS Simple Module

- The DSM series is based on DINGS platform products and combines high precision screw stepper motors with linear rail guidance.

- The linear module in the DSM series has a compact structure and high positioning accuracy which enables mechanical miniaturization.

- For example, DSM 35 mm offers good precision and many customization options for stroke length and pitch (link to Dings).

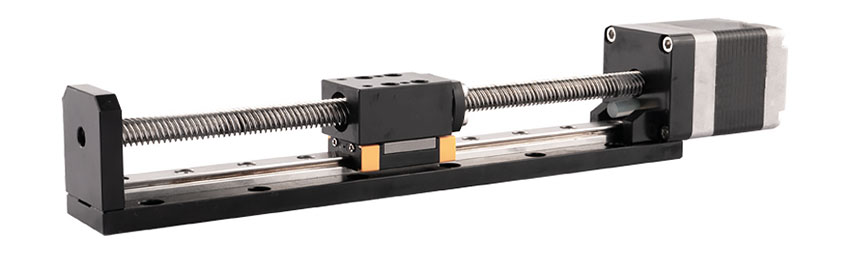

DLM – DINGS Compact electric Linear Module

- The DLM series is also a high-performance linear module driven by Dings stepper motors.

- The series is designed to be compact and has high positioning accuracy.

- In DLM, the rail is permanently mounted on an aluminum base, making it easy to use.

Of course, it is also possible to combine several complete linear units into multi-axis XYZ systems

If you want to know which complete linear unit does the job in analytical equipment, medical technology instruments, analytical labs, or another type of commercial application, get in touch directly!