Compact and powerful – the MC 3603 miniature motion controller

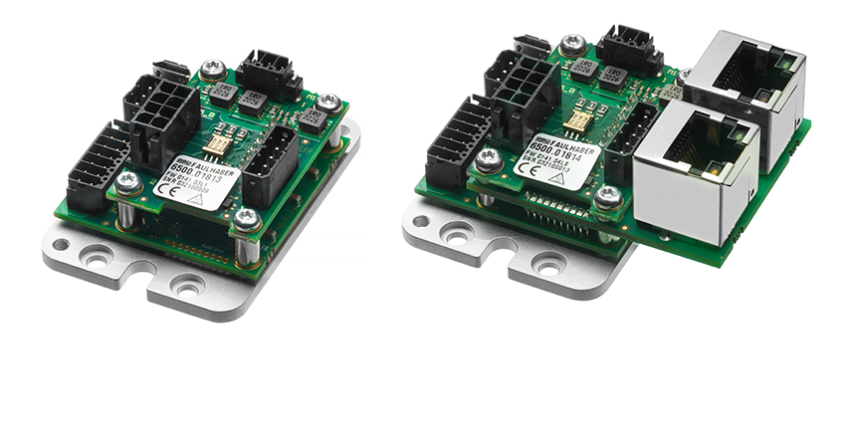

FAULHABER have recently expanded its product lineup with an innovative addition—the MC 3603 miniature motion controller, a game-changer designed without a housing for seamless integration. Read more

·