Enjoy your summer!

Here at Compotech, time for vacation is coming up. Some colleagues have already started theirs, while others are next in line. However, our offices will be staffed throughout the summer, so don’t hesitate to reach out if you need assistance. During the summer, we are open from 08:15 to 16:30 Monday to Thursday. On Fridays in July, we are open from 08:15 to 12:00, and in June & August from 08:15 to 15:00.

We wish all our customers, suppliers, our staff, followers, and stakeholders a joyful summer!

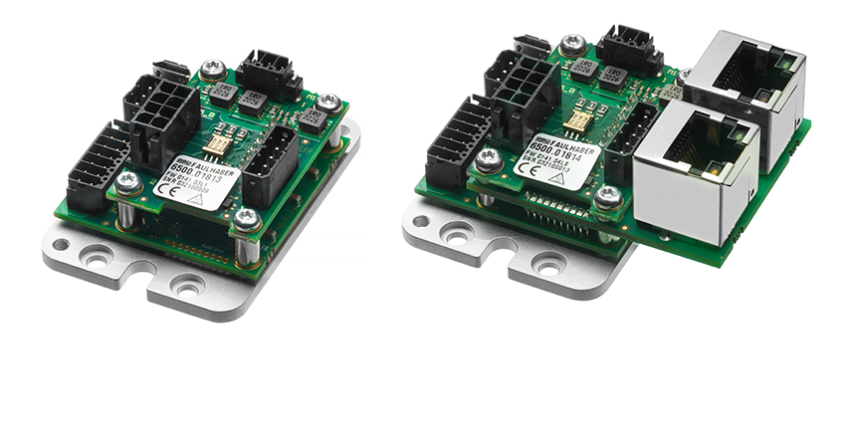

Compact and powerful – the MC 3603 miniature motion controller

FAULHABER have recently expanded its product lineup with an innovative addition—the MC 3603 miniature motion controller, a game-changer designed without a housing for seamless integration. Read more

Register for the upcoming FAULHABER webinar 6 June 11-12!

Don´t miss out this opportunity for better understanding of the thermal behaviour of FAULHABER stepper motors! This time you will learn how the working conditions and parameters impact the temperature and how reduce the temperature in an application. Additionally, after attending the webinar 4 June, you´ll also know the difference between the ON and OFF modes and what should be considered when powering OFF a stepper motor!

If you are interested in a webinar but do not have time to attend, please register anyway and you will receive the link to the recording by e-mail.

Enjoy your summer!

Here at Compotech, time for vacation is coming up. Several colleagues have already started theirs, while others are next in line. However, our offices will be staffed throughout the summer, so don’t hesitate to reach out if you need assistance. We look forward to an autumn full of new challenges. Until then, we wish all you all a joyful summer.

Congratulations Compotech – Addtech’s Entrepreneur of the Year!

We are incredibly proud and delighted to receive the prestigious Entrepreneur of the Year award within Addtech. In competition from 150 other sister companies with similar operations, we emerged as the winners of this esteemed prize!

Webinar: Step into the world of gearhead technologies

Don’t miss the opportunity to deepen your understanding of FAULHABER gearhead technologies. This time FAULHABER will delve into the world of gearhead technologies, providing you with a comprehensive comparison that will help you make informed decisions.

This time FAULHABER will shed light on the impact of backlash and how it can be effectively reduced. Backlash is a common concern in many drive systems, and understanding its effects is crucial for achieving optimal performance. The FAULHABER experts will share practical strategies to minimize backlash and enhance positioning stability and accuracy.

Moreover, the significance of selecting the right gearhead technology for a project. Showcase of real world applications of successful integration of motor, gearhead, and encoder combinations, enabling you to complete your drive system flawlessly, will be made.

Merry Christmas & A Happy New Year

Our best wishes for a Merry Christmas and a new year of continued teamwork. Thank you all our customers, suppliers and partners for all the great collaborations during 2022. We look forward to expand and develop our collaborations even further in 2023.

Drive systems for medical & laboratory equipment

Robotics and automation have long been standard in production. In the world of the medical industry, they are becoming increasingly important. This is due, on the one hand, to a gain in efficiency and comfort – to say nothing of the cost savings – and, on the other hand, to the innovative drive solutions that ensure trust in the most demanding of applications: From local, office-based analysis systems to fully automated, large-scale laboratories, from functional prostheses to portable medication dosing units and even surgery robots, FAULHABER drive components are the first choice here. In addition to the high standards of EN ISO 9001 and 14001, FAULHABER is also specially certified for medical products acc. to EN ISO 13485.

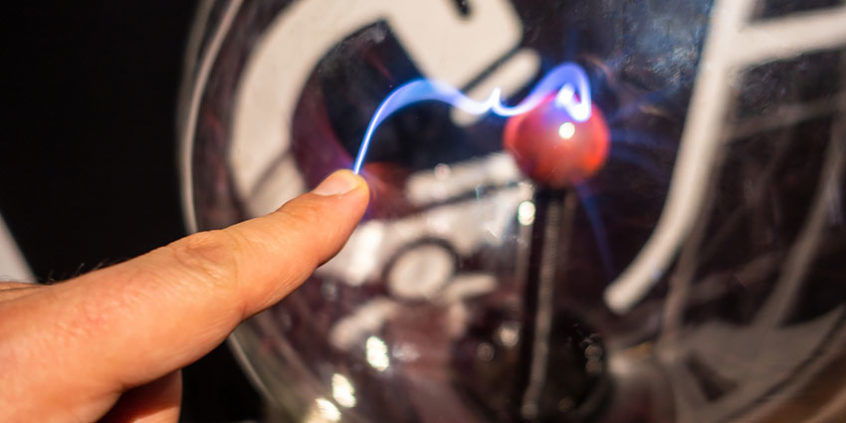

GUIDE: Avoid electrostatic discharge when handling PCB or electronics

The world of ESD-protection (Electrostatic Discharge), is vast and there are lots of regulations around the matter. Below are a three tips to save your product or even your life! Our hope is that you can use this information to reduce loss and increase quality. Read more

Merry Christmas & A Happy New Year!

Season’s Greetings and our best wishes for a Prosperous New Year. Thank you, all our customers and suppliers, for all the great collaborations during 2020!