GUIDE: Avoid electrostatic discharge when handling PCB or electronics

The world of ESD-protection (Electrostatic Discharge), is vast and there are lots of regulations around the matter. Below are a three tips to save your product or even your life! Our hope is that you can use this information to reduce loss and increase quality.

1. In-line resistor

We normally just buy an ESD mat or wrist strap and connect to the electrical socket ground and wear the strap. If you had a cheap strap laying around and when I measure the resistance between the wrist strap (that is in contact with my body) and the mains ground I got zero ohms. Which seems like it works but that is a hazard. There should be between 1-10 MΩ (mega ohms) between the wrist strap and the grounding point. If there were to be a fault in the mains wiring you could get electrocuted and DIE. Please check the ones you have at the labs. Note that there are some ESD product which does not have a resistor because they are meant to connect to devices such as a soldering station.

2. Cordless Wrist strap

There is for some odd reason a large amount of wrist strap without cables. These do not work and do not trust them. We could dive into the physics but take my words and stick to the wired straps.

3. ESD bags and Sponges

Sometimes you test a PCB or electrical component that works well and after shipment nothing works or there is some fault with the product. This can be due to ESD when shipping. The best bag to use is the one with a conductive lining which creates a Faraday’s cage and protect against all external discharges. The blue and pink zip lock bags are also good but those don’t generate ESD but does not protect from external zaps (known as dissipative since they do not build up static).

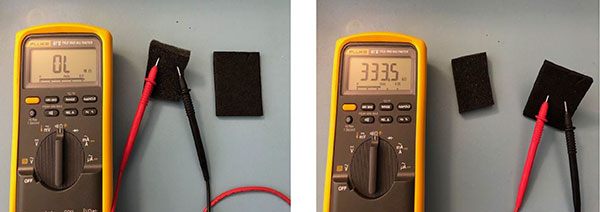

There are also several type of sponges, the proper one to use is conductive. If you measure resistance on a 1cm piece of sponge you should get between 0.3-5 MΩ resistance. If you ship an IC or PCB with exposed pins, it is nice to push the pins through such a sponge so that all pins are “shorted” together. If there was to be a discharge, the current has nowhere to travel withing the PCB since there is no return path. Photo below shows this test, they can look similar but behave very different.

Summary – properly handling and the product will perform best

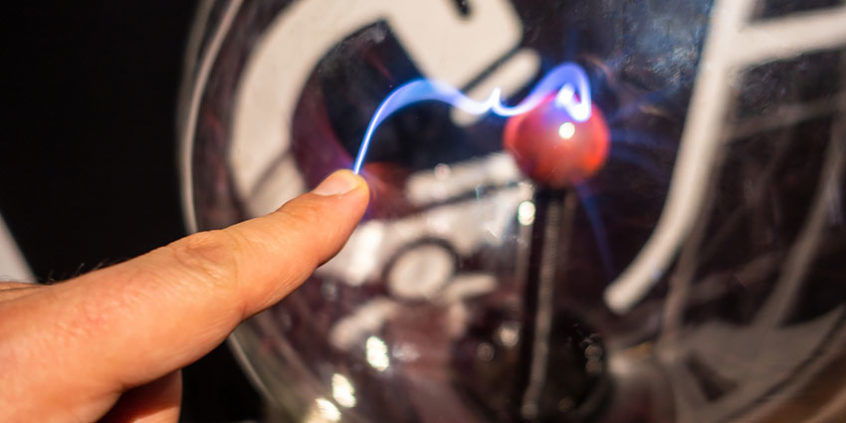

Be aware when handling PCB or electronics. Don’t poke fingers into connectors or go across a carpetted office and then touch electronics. This could ruin your day. If you need to make sure that you are discharged, you can always just touch a metallic surface such as the metal case of your computer which will help a bit.