GUIDE: Common problems with encoders and troubleshooting tips

Encoders are integral components in many motion control systems, providing critical feedback to motors for position, speed, and direction control. However, like any mechanical or electrical device, encoders can sometimes encounter problems that disrupt system performance. Identifying and resolving these issues quickly is essential to maintaining the reliability and efficiency of your system.

In this article, we’ll explore some of the most common problems with encoders and offer troubleshooting tips to help you diagnose and fix them. Read more

Choosing the Right Encoder for Motors: Key Considerations

When selecting an encoder for a motor system, several factors across electrical, mechanical, and software aspects need to be carefully evaluated. Encoders play a vital role in measuring the position, speed, and direction of the motor shaft, providing essential feedback for motor controllers in a variety of applications. A poorly chosen encoder can lead to poor system performance, increased wear and tear, or even system failure. This article provides a comprehensive guide to understanding the key factors to consider when selecting an encoder for motors. Read more

Drive system & components for smart farming

Do you want your company to grow better & smarter with drive systems for agricultural robotics?

Do you have thoughts about drive system & components for smart farming? Perhaps you have challenges regarding the specific requirements regarding speed, power, precision, positioning or ingress protection?

Drive systems can be done in many different ways, with different advantages and disadvantages, depending on requirements. Drive systems specifically for agricultural robotics will for example probably meet a humid environment and can be a challenge in itself.

When involving us in your project, you advantage a partner of more than 30 year’s experience in drive system – and that will probably make all the difference in your project. Want to know more? We´re keen to be involved in your motion challenges regarding the specific requirements for your application!

Do complete linear units fit in your application?

Congratulations, you can then significantly simplify the design work. With stepper motor-driven complete linear units & guides, the support already done, you just need to mount your load. Read more

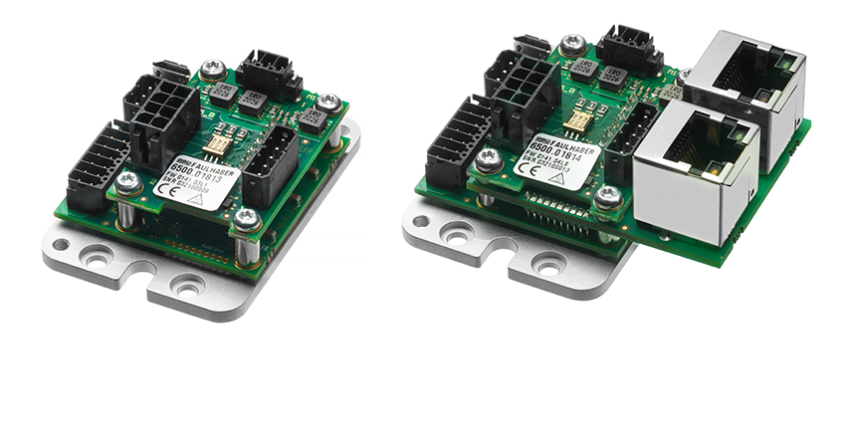

Compact and powerful – the MC 3603 miniature motion controller

FAULHABER have recently expanded its product lineup with an innovative addition—the MC 3603 miniature motion controller, a game-changer designed without a housing for seamless integration. Read more

A golf robot for automating the world’s driving ranges!

The golf robot Range Picker is at the top of many golf clubs’ wish lists. However, Range Picker is already in use at clubs like PGA Frisco in Texas, Deer Walley Golf Range in Georgia, Seve Golf Center in Rotterdam and Troxhammar GK in Sweden. In Sweden, for instance, golf is the third most popular sport, and globally there are more than 60 million golfers. Therefore, the potential for Relox Robotics – the company behind Range Picker – is enormous. Read more

WEBINAR: Unlocking the secrets of sensors with FAULHABER

Everything you need to know but were afraid to ask regarding sensors. Join FAULHABER in this webinar and explore the world of sensors and encoders utilized in FAULHABER drive systems. This time you´ll get insights into motor operation, both with and without sensors, and delve into the similarities among various sensor technologies. Gain valuable advice on selecting the optimal sensor and encoder technology tailored to your specific application requirements.

When: Tuesday, February 27 at 11:00 – 12:00 AM

Webinar: Optimized logistics with state-of-the-art drive systems!

Join the upcoming webinar and discover how to choose the perfect FAULHABER drive systems for your logistics applications.

Whether it’s conveyor belts, lifters, grippers, AGV robots, or camera PTZ control, incorporating high-quality drive systems can greatly enhance performance and efficiency.

In this webinar, FAULHABER will take you on a journey from defining your specific requirements to selecting a complete drive system tailored to your application.The FAULHABER experts will provide valuable insights, explaining diagrams, and sharing tips and tricks to help you choose the ideal motion source for your next project.

Webinar: Step into the world of gearhead technologies

Don’t miss the opportunity to deepen your understanding of FAULHABER gearhead technologies. This time FAULHABER will delve into the world of gearhead technologies, providing you with a comprehensive comparison that will help you make informed decisions.

This time FAULHABER will shed light on the impact of backlash and how it can be effectively reduced. Backlash is a common concern in many drive systems, and understanding its effects is crucial for achieving optimal performance. The FAULHABER experts will share practical strategies to minimize backlash and enhance positioning stability and accuracy.

Moreover, the significance of selecting the right gearhead technology for a project. Showcase of real world applications of successful integration of motor, gearhead, and encoder combinations, enabling you to complete your drive system flawlessly, will be made.

Webinar: Straight to the point with linear actuators.

Dont´t forget to attend the FAULHABER webinar April 27. This time you´ll explore the topic of converting rotary motion to linear motion using a screw. With so many different options available when it comes to type of motors and screws, it can be challenging to identify the best technology for your needs. However, after attending the webinar April 27, you’ll be equipped with the knowledge and insights in advantages and disadvantages of different technologies for creating linear motion.