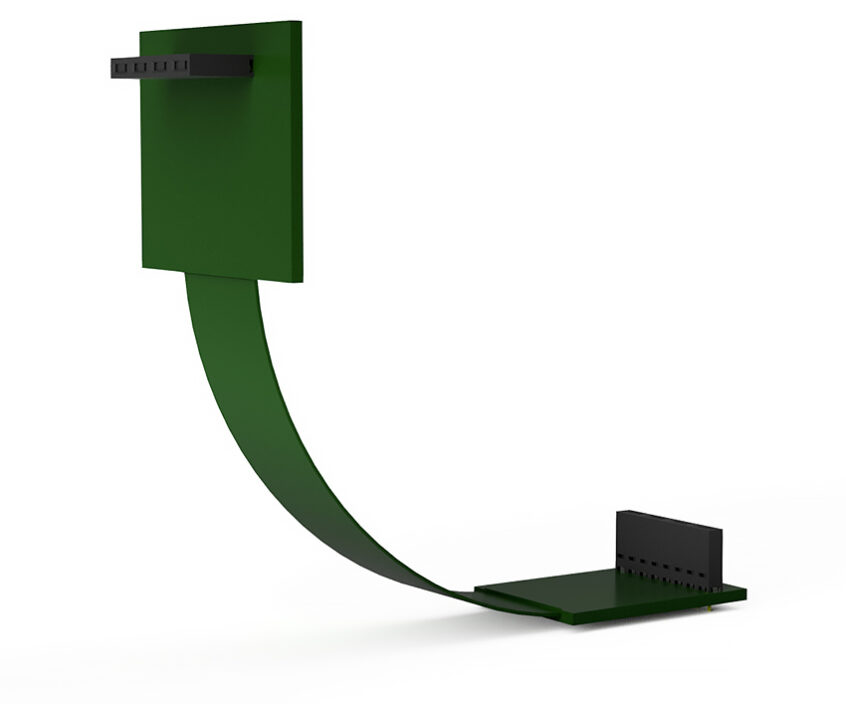

Rigid Flex PCB

Rigid Flex PCB which will get rid of the wires, crimping, stripping and soldering. The one PCB will be a complete unit and if the design is done right it cannot be wired wrong due to human error.

As the name implies, is a complete PCB which has a rigid section and a flexible section. This technique is used a lot in compact devices such as laptops or mobile phones. At Compotech we can use similar technique for other applications and bring new optimizations in performance, quality and costs. This may also save precious time spent in soldering and inspection which will now be done through the PCB process and by automated test equipment.

Our design process is done in-house for best control of the end product. The flex PCB will allow for one batch to be done within 25 days whereas the original wired version took over 4 months for the same size of batch.

Want to know more? We´re keen to be involved in your project!