Event at KTH – an international leading technical university

We are excited to participate in Potential, an event hosted annually by the Royal Electrical Section at KTH in Stockholm. On Friday, January 17th, it’s happening – we look forward to discussing challenges, sharing insights, tips, knowledge, and above all, the opportunity to meet and support the future engineers who will be in attendance.

Know more about Potential (in Swedish)

Success in Nordic Lift Expo´ trade show

A heartfelt thank you to everyone who visited us and contributed to making our participation at Nordic Lift Expo this week such a resounding success!

A special thanks to CEDES and David Wallen at CEDES for participating with us and sharing insights and expertise that brings a new level of safety and efficiency to elevator operations. We’re thrilled to have had the chance to showcase some of the future predictive maintenance for elevators.

Events like these are a wonderful opportunity to connect, share ideas, and explore the future of electronics together. We’re already looking forward to the next occasion to meet and exchange ideas.

Compotech and CEDES welcome you to Nordic Lift Expo!

The Nordic Lift Expo is taking place only today 12 November at Infra City in Upplands Väsby. We – Compotech Provider AB and CEDES will show exciting news and this fair in particular is an excellent opportunity to acquire new knowledge, exchange experiences and mingle with industry colleagues in the elevator industry.

We will for example showcase the future of predictive maintenance for elevators brings a new level of safety and efficiency to elevator operations.

Welcome – meet us at 3:11 in Infra City!

Drive system & components for smart farming

Do you want your company to grow better & smarter with drive systems for agricultural robotics?

Do you have thoughts about drive system & components for smart farming? Perhaps you have challenges regarding the specific requirements regarding speed, power, precision, positioning or ingress protection?

Drive systems can be done in many different ways, with different advantages and disadvantages, depending on requirements. Drive systems specifically for agricultural robotics will for example probably meet a humid environment and can be a challenge in itself.

When involving us in your project, you advantage a partner of more than 30 year’s experience in drive system – and that will probably make all the difference in your project. Want to know more? We´re keen to be involved in your motion challenges regarding the specific requirements for your application!

Do complete linear units fit in your application?

Congratulations, you can then significantly simplify the design work. With stepper motor-driven complete linear units & guides, the support already done, you just need to mount your load. Read more

Enjoy your summer!

Here at Compotech, time for vacation is coming up. Some colleagues have already started theirs, while others are next in line. However, our offices will be staffed throughout the summer, so don’t hesitate to reach out if you need assistance. During the summer, we are open from 08:15 to 16:30 Monday to Thursday. On Fridays in July, we are open from 08:15 to 12:00, and in June & August from 08:15 to 15:00.

We wish all our customers, suppliers, our staff, followers, and stakeholders a joyful summer!

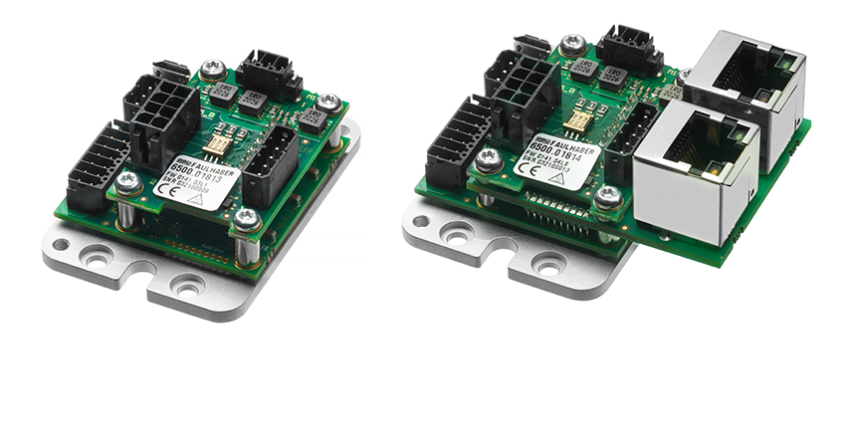

Compact and powerful – the MC 3603 miniature motion controller

FAULHABER have recently expanded its product lineup with an innovative addition—the MC 3603 miniature motion controller, a game-changer designed without a housing for seamless integration. Read more

Register for the upcoming FAULHABER webinar 6 June 11-12!

Don´t miss out this opportunity for better understanding of the thermal behaviour of FAULHABER stepper motors! This time you will learn how the working conditions and parameters impact the temperature and how reduce the temperature in an application. Additionally, after attending the webinar 4 June, you´ll also know the difference between the ON and OFF modes and what should be considered when powering OFF a stepper motor!

If you are interested in a webinar but do not have time to attend, please register anyway and you will receive the link to the recording by e-mail.

Go to FAULHABER and register now.

A golf robot for automating the world’s driving ranges!

The golf robot Range Picker is at the top of many golf clubs’ wish lists. However, Range Picker is already in use at clubs like PGA Frisco in Texas, Deer Walley Golf Range in Georgia, Seve Golf Center in Rotterdam and Troxhammar GK in Sweden. In Sweden, for instance, golf is the third most popular sport, and globally there are more than 60 million golfers. Therefore, the potential for Relox Robotics – the company behind Range Picker – is enormous. Read more

WEBINAR: Unlocking the secrets of sensors with FAULHABER

Everything you need to know but were afraid to ask regarding sensors. Join FAULHABER in this webinar and explore the world of sensors and encoders utilized in FAULHABER drive systems. This time you´ll get insights into motor operation, both with and without sensors, and delve into the similarities among various sensor technologies. Gain valuable advice on selecting the optimal sensor and encoder technology tailored to your specific application requirements.

When: Tuesday, February 27 at 11:00 – 12:00 AM