FAULHABER webinar

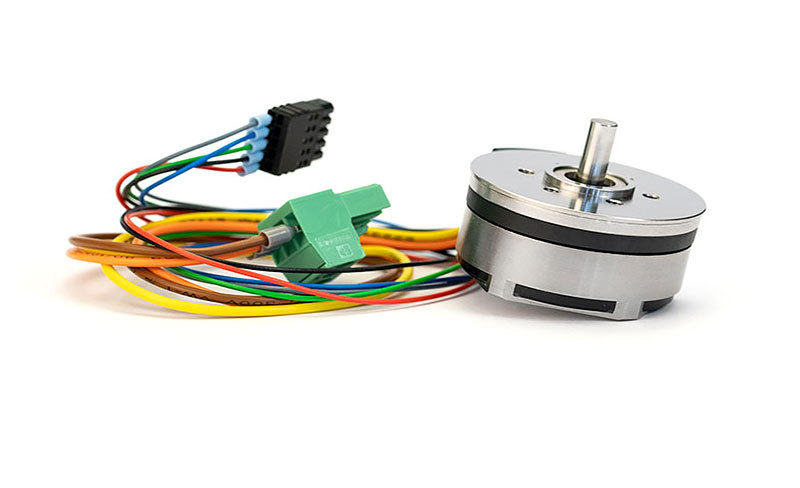

Are you looking for a flat and compact motor that surpasses most in terms of torque and length-to-volume/weight ratio? Then you should sign up for FAULHABER’s webinar on September 26th. You will gain knowledge about a special winding technology that provides exceptionally high torque and efficiency. FAULHABER will also explore application examples and how to select drive systems using the FAULHABER Drive Calculator.

Date:Tuesday, September 26, 11:00 AM – 12:00 PM CEST

Enjoy your summer!

Here at Compotech, time for vacation is coming up. Several colleagues have already started theirs, while others are next in line. However, our offices will be staffed throughout the summer, so don’t hesitate to reach out if you need assistance. We look forward to an autumn full of new challenges. Until then, we wish all you all a joyful summer.

Congratulations Compotech – Addtech’s Entrepreneur of the Year!

We are incredibly proud and delighted to receive the prestigious Entrepreneur of the Year award within Addtech. In competition from 150 other sister companies with similar operations, we emerged as the winners of this esteemed prize!

Webinar: Optimized logistics with state-of-the-art drive systems!

Join the upcoming webinar and discover how to choose the perfect FAULHABER drive systems for your logistics applications.

Whether it’s conveyor belts, lifters, grippers, AGV robots, or camera PTZ control, incorporating high-quality drive systems can greatly enhance performance and efficiency.

In this webinar, FAULHABER will take you on a journey from defining your specific requirements to selecting a complete drive system tailored to your application.The FAULHABER experts will provide valuable insights, explaining diagrams, and sharing tips and tricks to help you choose the ideal motion source for your next project.

Webinar: Step into the world of gearhead technologies

Don’t miss the opportunity to deepen your understanding of FAULHABER gearhead technologies. This time FAULHABER will delve into the world of gearhead technologies, providing you with a comprehensive comparison that will help you make informed decisions.

This time FAULHABER will shed light on the impact of backlash and how it can be effectively reduced. Backlash is a common concern in many drive systems, and understanding its effects is crucial for achieving optimal performance. The FAULHABER experts will share practical strategies to minimize backlash and enhance positioning stability and accuracy.

Moreover, the significance of selecting the right gearhead technology for a project. Showcase of real world applications of successful integration of motor, gearhead, and encoder combinations, enabling you to complete your drive system flawlessly, will be made.

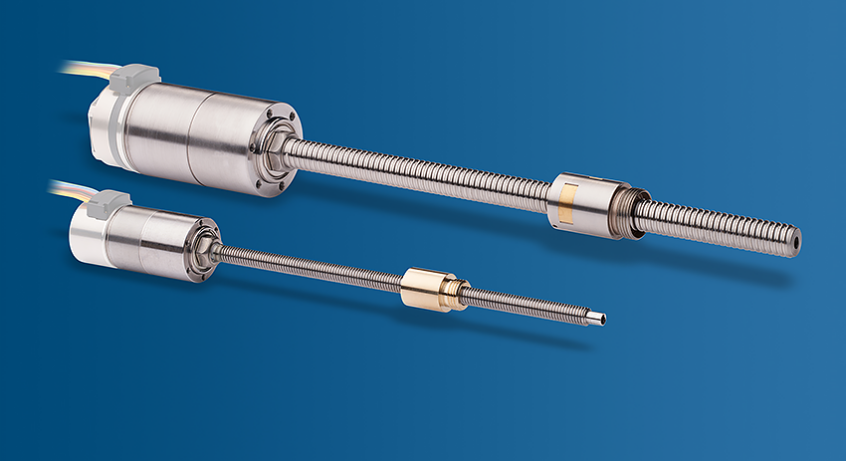

Webinar: Straight to the point with linear actuators.

Dont´t forget to attend the FAULHABER webinar April 27. This time you´ll explore the topic of converting rotary motion to linear motion using a screw. With so many different options available when it comes to type of motors and screws, it can be challenging to identify the best technology for your needs. However, after attending the webinar April 27, you’ll be equipped with the knowledge and insights in advantages and disadvantages of different technologies for creating linear motion.

Go to FAULHABER and register now (link)

FAULHABER: Linear Actuator L

The FAULHABER Linear Actuator L series are designed to provide high performances in compact dimensions, these actuators can support large input speed, high output force and are suited for a wide range of applications like robotics, industrial machines and laboratory equipment.

A large number of reduction ratios, uniformly distributed, are available to select the most appropriate configuration to fit various force or speed operating points as required by the application.

This new family also grants high flexibility offering different screw sizes and types; moreover a large selection of options is available to match different ambient conditions and make mechanical integration inside applications faster and smoother through various flange and nut configurations.

Combined with FAULHABER’s wide range of DC motors, brushless motors and stepper motors, you can tailor a complete solution to suit your requirements. Want to know more? Ask us and we’ll be happy to tell you more.

White Paper: Forms of closed loop stepper control.

Stepper motors are employed in a variety of applications across the engineering spectrum because they are inexpensive, simple to operate, and offer high torque at low speeds. However, stepper motors suffer from drawbacks such as missed steps, decreased torque at high speeds, resonances, and high power consumption. In order to mitigate these issues, Galil has three methods of closing the loop around a stepper motor: End point correction, closed loop microstepping, and driving the stepper motor as a 2-phase brushless motor.

Accuracy with stepper motors

Don’t miss out today’s webinar, join FAULHABER and gain key insights into accuracy with stepper motors. Discover the fundamental theoretical basis behind accuracy and precision. And explore the various elements that influence stepper motor accuracy. The FAULHABER experts will also delve into topics such as accuracy when stepper motors are combined with linear components or encoders. To top it off – showcase the use of the FAULHABER Drive Calculator to help you select the optimal stepper motor combination.

Register now to secure your spot today, 28 March 11:00 AM (link)

Merry Christmas & A Happy New Year

Our best wishes for a Merry Christmas and a new year of continued teamwork. Thank you all our customers, suppliers and partners for all the great collaborations during 2022. We look forward to expand and develop our collaborations even further in 2023.