Enjoy your summer!

Here at Compotech, time for vacation is coming up. Some colleagues have already started theirs, while others are next in line. However, our offices will be staffed throughout the summer, so don’t hesitate to reach out if you need assistance. During the summer, we are open from 08:15 to 16:30 Monday to Thursday. On Fridays in July, we are open from 08:15 to 12:00, and in June & August from 08:15 to 15:00.

We wish all our customers, suppliers, our staff, followers, and stakeholders a joyful summer!

Register for the upcoming FAULHABER webinar 6 June 11-12!

Don´t miss out this opportunity for better understanding of the thermal behaviour of FAULHABER stepper motors! This time you will learn how the working conditions and parameters impact the temperature and how reduce the temperature in an application. Additionally, after attending the webinar 4 June, you´ll also know the difference between the ON and OFF modes and what should be considered when powering OFF a stepper motor!

If you are interested in a webinar but do not have time to attend, please register anyway and you will receive the link to the recording by e-mail.

WEBINAR: Grow better, grow smarter with FAULHABER drive systems for agricultural robotics

It’s almost time for the next FAULHABER webinar, and this time you will go through drive packages adapted for application requirements in agricultural robotics. In this webinar you will see how compact, high-quality and long lifetime drive systems can be used for smart farming applications.

Topics:

-

Drive system components for smart farming

-

Combinations and special design

-

Tips and tricks for agricultural applications

-

Speed and motion control systems in agricultural robotics

-

Drive system selection for smart farming applications

Date & Time: Secure your spot and mark your calendar for the webinar on April 16 11:00 AM – 12:00 PM.

A golf robot for automating the world’s driving ranges!

The golf robot Range Picker is at the top of many golf clubs’ wish lists. However, Range Picker is already in use at clubs like PGA Frisco in Texas, Deer Walley Golf Range in Georgia, Seve Golf Center in Rotterdam and Troxhammar GK in Sweden. In Sweden, for instance, golf is the third most popular sport, and globally there are more than 60 million golfers. Therefore, the potential for Relox Robotics – the company behind Range Picker – is enormous. Read more

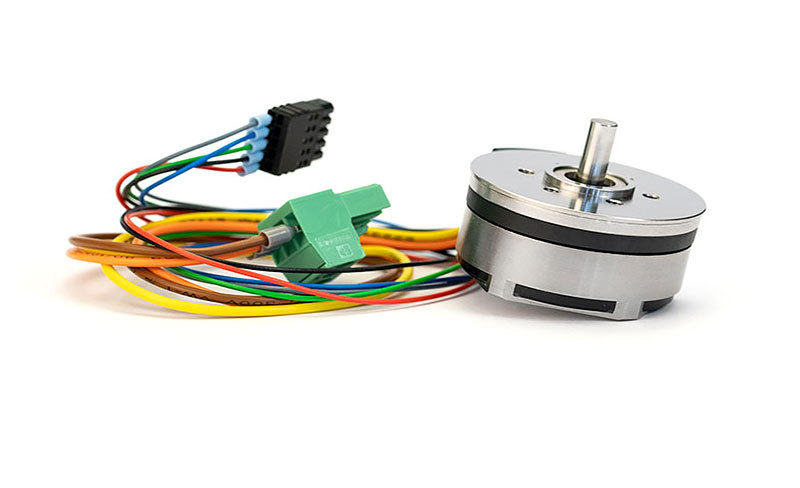

WEBINAR: Unlocking the secrets of sensors with FAULHABER

Everything you need to know but were afraid to ask regarding sensors. Join FAULHABER in this webinar and explore the world of sensors and encoders utilized in FAULHABER drive systems. This time you´ll get insights into motor operation, both with and without sensors, and delve into the similarities among various sensor technologies. Gain valuable advice on selecting the optimal sensor and encoder technology tailored to your specific application requirements.

When: Tuesday, February 27 at 11:00 – 12:00 AM

FAULHABER webinar

Are you looking for a flat and compact motor that surpasses most in terms of torque and length-to-volume/weight ratio? Then you should sign up for FAULHABER’s webinar on September 26th. You will gain knowledge about a special winding technology that provides exceptionally high torque and efficiency. FAULHABER will also explore application examples and how to select drive systems using the FAULHABER Drive Calculator.

Date:Tuesday, September 26, 11:00 AM – 12:00 PM CEST

Enjoy your summer!

Here at Compotech, time for vacation is coming up. Several colleagues have already started theirs, while others are next in line. However, our offices will be staffed throughout the summer, so don’t hesitate to reach out if you need assistance. We look forward to an autumn full of new challenges. Until then, we wish all you all a joyful summer.

Webinar: Optimized logistics with state-of-the-art drive systems!

Join the upcoming webinar and discover how to choose the perfect FAULHABER drive systems for your logistics applications.

Whether it’s conveyor belts, lifters, grippers, AGV robots, or camera PTZ control, incorporating high-quality drive systems can greatly enhance performance and efficiency.

In this webinar, FAULHABER will take you on a journey from defining your specific requirements to selecting a complete drive system tailored to your application.The FAULHABER experts will provide valuable insights, explaining diagrams, and sharing tips and tricks to help you choose the ideal motion source for your next project.

Webinar: Step into the world of gearhead technologies

Don’t miss the opportunity to deepen your understanding of FAULHABER gearhead technologies. This time FAULHABER will delve into the world of gearhead technologies, providing you with a comprehensive comparison that will help you make informed decisions.

This time FAULHABER will shed light on the impact of backlash and how it can be effectively reduced. Backlash is a common concern in many drive systems, and understanding its effects is crucial for achieving optimal performance. The FAULHABER experts will share practical strategies to minimize backlash and enhance positioning stability and accuracy.

Moreover, the significance of selecting the right gearhead technology for a project. Showcase of real world applications of successful integration of motor, gearhead, and encoder combinations, enabling you to complete your drive system flawlessly, will be made.

Webinar: Straight to the point with linear actuators.

Dont´t forget to attend the FAULHABER webinar April 27. This time you´ll explore the topic of converting rotary motion to linear motion using a screw. With so many different options available when it comes to type of motors and screws, it can be challenging to identify the best technology for your needs. However, after attending the webinar April 27, you’ll be equipped with the knowledge and insights in advantages and disadvantages of different technologies for creating linear motion.