Merry Christmas & A Happy New Year!

Season’s Greetings and our best wishes for a Prosperous New Year. Thank you, all our customers and suppliers, for all the great collaborations during 2020!

We are moving to new premises!

We are relocating our office and storage warehouse into larger and more modern facilities. In a couple of months, we will take possession of our new Alvik office in the area of Stockholm. But before that, we will move the logistics function to Landvetter in the area of Gothenburg.

Details on storage warehouse location

The new warehouse address is valid from 16 October.

Compotech Provider AB

c/o Vätterleden Logistik AB

Logistikvägen 6

438 70 LANDVETTER

SWEDEN

The new visiting and postal address

The new visiting and postal address is valid from 1st December.

Compotech Provider AB

Gustavslundsvägen 145, 4 tr

167 51 BROMMA

SWEDEN

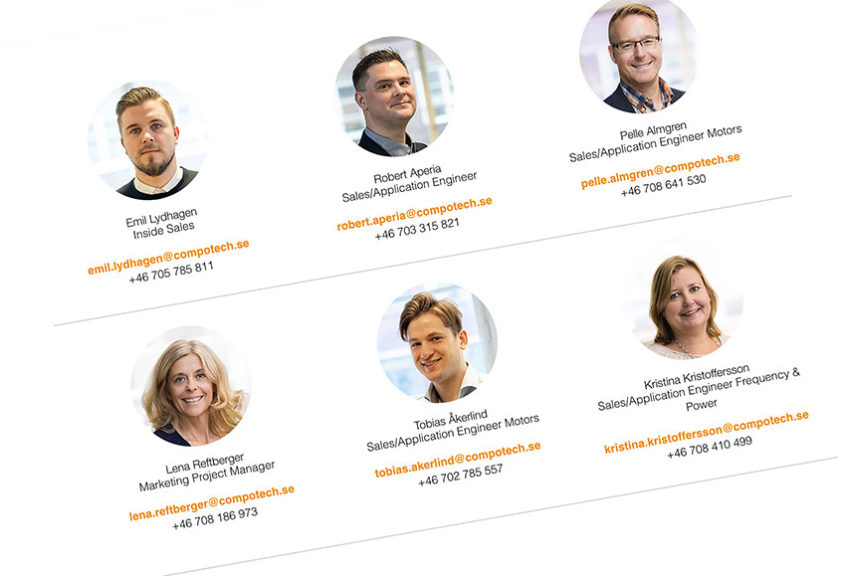

Please contact our order and logistics function team for further details.

Experience higher accuracy measurement in harsh environments

Celera Motion announces the expansion of its Zettlex Ultra IncOder™ series of inductive angle encoders with the introduction of the new Mini Ultra and, continued growth of the Midi Ultra. Celera Motion’s Zettlex encoders use a unique, inductive technology that employs the use of printed circuit boards (PCBs). These encoders are non-contact devices which allow precision measurement of angle or angular speed in harsh environments where traditional capacitive and magnetic devices can be unreliable. Each Ultra IncOder unit is pre-calibrated and offers up to 19 arc-seconds accuracy depending on size. Read more

Normal delivery capacity and operation during Corona pandemic

During these peculiar times, we continue to develop everything from simple solutions to pioneering advances for optimum levels of engineering precision and efficiency.

We´re keen on taking part of solving the challenges you may face in your industrial application.

Deliveries

Presently regular lead times apply on deliveries. We have not been affected by interference in the form of delivery problems to any significant extent. However, we may need to adjust delivery times and/or deliver partial orders in the event of any possible factory impact.

LedgeCircle – 35 mm innovation that lights the way

Well thought-out lighting and a fresh appearance from the moment you step into the office was the idea behind the LedgeCircle ceiling range from the technology company DEFA. With a thickness of 35 mm – and world-class control options – the company itself points out that you can obtain a fresh and lightweight luminaire which is suitable for both walls and ceilings. Read more

DC motors in Ironhand® – the world’s first soft robotic muscle strengthening system for professional users

Ironhand’s® pioneering system has been developed to prevent and detect risks of repetitive strain injuries from grip-intensive tasks. The system combines neuroscience, mechatronics and robotics with unique digital functions and strengthens the user’s grip and endurance.

Intelligent light control to minimise waste

Fifty per cent. Pick a company at random and there is a high risk that much of their electricity consumption on lighting is wasted. Lamps are on even though nobody is there. The ‘last one out turns off the lights’ approach is a principle that has never worked anywhere. Read more

Say Hello to Our New Quality Manager from Ericsson!

A few months ago, we expanded Compotech into the Benelux region, we did also present our new CEO about the same time. Now we´re expanding our comprehensive quality work!

We already have an established quality organisation working on-site in Asia, and now we are strengthening our headquarters with an experienced quality manager. Rashin Kabiri has, among other things, been responsible for quality assurance at Ericsson and Sony Ericsson, and she holds a master’s degree in Mathematical Statistics from Stockholm University. This recruitment gives us unique skills to further develop our suppliers and ourselves. Rashin will focus on collaborating with customers and suppliers through proactive quality activities.

Welcome to Compotech, Rashin! Briefly tell us about your experiences from previous workplaces.

– I worked at Sony Ericsson for four years. It was a great place to work at, learning their high demands on quality, both externally and internally. My first position was as a Supplier Quality Engineer, before I became an Industrialization Project Quality Manager. I learned about the importance of having clearly defined processes and traceability in production and the daily work, says Rashin. After Sony Ericsson, I moved on to Ericsson, where I worked for seven years as a Verification and Quality Leader.

What will you contribute at Compotech?

– Having a good and open communication with our suppliers is truly important, in order to convey customers’ and Compotech’s quality requirements. I’m responsible for increasing the quality awareness. Through our supplier development program, we aim to bring about a higher level of process control and a better understanding of what is important for our customers. The customer’s benefit will be better and more robust products, more reliable delivery times, and improved control over the entire supply chain. These are the things that have become more and more important now when we no longer only sell components, but also develop complex solutions for our customers.

Our project model includes quality activities right from the feasibility study phase. Can you tell us more about it?

– I’m part of the engineering team here at Compotech, that are responsible for developing complex solutions. I am involved from the project start and work with the team and the customer, going through the specification. Our project model helps us to understand customer requirements and how to involve all necessary resources, both internally at the customer and externally through us, to be more efficient and to reduce lead times. This is a way of working I am used with from Ericsson and Sony Ericsson, so I know that it is a proven and effective method.

Last but not least, why did you choose to come work for us?

– I found it very exciting that quality and processes are something that permeates our entire way of working here. And I look forward to develop our processes even more and take the company to the next level, says Rashin.

Rashin is also a part of Compotech’s quality team, working on-site from Stockholm as well as Shenzhen and Shanghai. Together they carry out regular on-site audits at suppliers and sometime even accompanied by customers.

Rashin Kabiri started her position at Compotech February 1, 2017.

Motion Control for decentralised intelligence with EtherCAT from FAULHABER

Decentralised intelligence and the capacity for real-time communication with higher level process control technology and flexibility in usage applications are requirements for cutting-edge drive systems within the context of networked industry (cf. company box) has taken appropriate action and developed a new generation of motion controllers.