Direct-Drive Gimbals for UAVs – When Weight and Precision Must Work Together

The use of UAVs is increasing rapidly, along with the demand for gimbal systems that are lightweight, precise, and energy-efficient. For many development teams, the challenge lies in combining high performance with a compact design where every gram counts.

We see that traditional gimbal solutions often reach their limits in terms of weight and power consumption. At the same time, modern UAV applications require extremely high stability and accurate positioning. As a result, more and more designers are turning to direct-drive solutions without gearboxes, an approach that delivers high pointing accuracy, reliability, and a more compact overall design.

For direct-drive gimbals in UAV applications, low-profile motors from the Omni and Agility series by Celera Motion (Novanta) are particularly well suited. These motors offer low power consumption and can be customized with through-holes, providing greater flexibility in mechanical design.

Achieving stable and accurate positioning also requires encoders with high resolution in a compact form factor. Optira encoders from Celera Motion are developed for applications where low weight, high positional accuracy, and excellent repeatability are critical.

By combining the right motor and encoder solutions, we help our customers develop direct-drive gimbals that meet demanding requirements for precision, energy efficiency, and low weight, without compromising performance.

Would you like to discuss your application with us?

At Compotech, we are happy to support you with technical advice and guidance in selecting motors and encoders. Contact us to learn more.

Success in Nordic Lift Expo´ trade show

A heartfelt thank you to everyone who visited us and contributed to making our participation at Nordic Lift Expo this week such a resounding success!

A special thanks to CEDES and David Wallen at CEDES for participating with us and sharing insights and expertise that brings a new level of safety and efficiency to elevator operations. We’re thrilled to have had the chance to showcase some of the future predictive maintenance for elevators.

Events like these are a wonderful opportunity to connect, share ideas, and explore the future of electronics together. We’re already looking forward to the next occasion to meet and exchange ideas.

Congratulations Compotech – Addtech’s Entrepreneur of the Year!

We are incredibly proud and delighted to receive the prestigious Entrepreneur of the Year award within Addtech. In competition from 150 other sister companies with similar operations, we emerged as the winners of this esteemed prize!

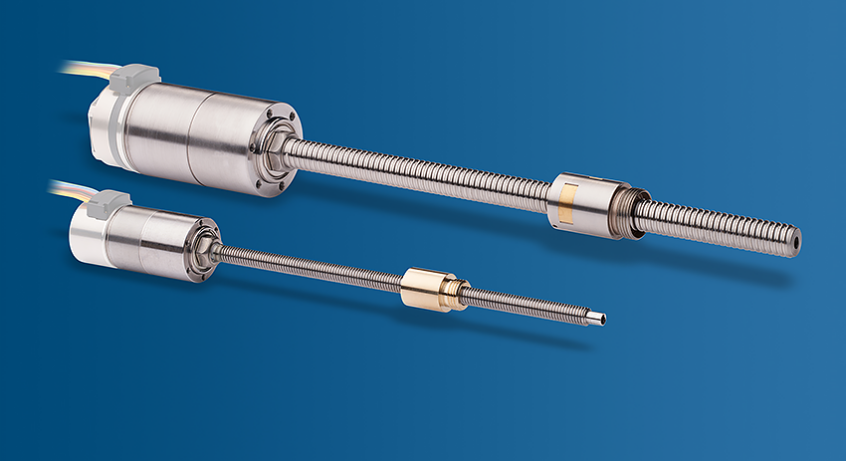

FAULHABER: Linear Actuator L

The FAULHABER Linear Actuator L series are designed to provide high performances in compact dimensions, these actuators can support large input speed, high output force and are suited for a wide range of applications like robotics, industrial machines and laboratory equipment.

A large number of reduction ratios, uniformly distributed, are available to select the most appropriate configuration to fit various force or speed operating points as required by the application.

This new family also grants high flexibility offering different screw sizes and types; moreover a large selection of options is available to match different ambient conditions and make mechanical integration inside applications faster and smoother through various flange and nut configurations.

Combined with FAULHABER’s wide range of DC motors, brushless motors and stepper motors, you can tailor a complete solution to suit your requirements. Want to know more? Ask us and we’ll be happy to tell you more.

Normal delivery capacity and operation during Corona pandemic

During these peculiar times, we continue to develop everything from simple solutions to pioneering advances for optimum levels of engineering precision and efficiency.

We´re keen on taking part of solving the challenges you may face in your industrial application.

Deliveries

Presently regular lead times apply on deliveries. We have not been affected by interference in the form of delivery problems to any significant extent. However, we may need to adjust delivery times and/or deliver partial orders in the event of any possible factory impact.

Say Hello to Our New Quality Manager from Ericsson!

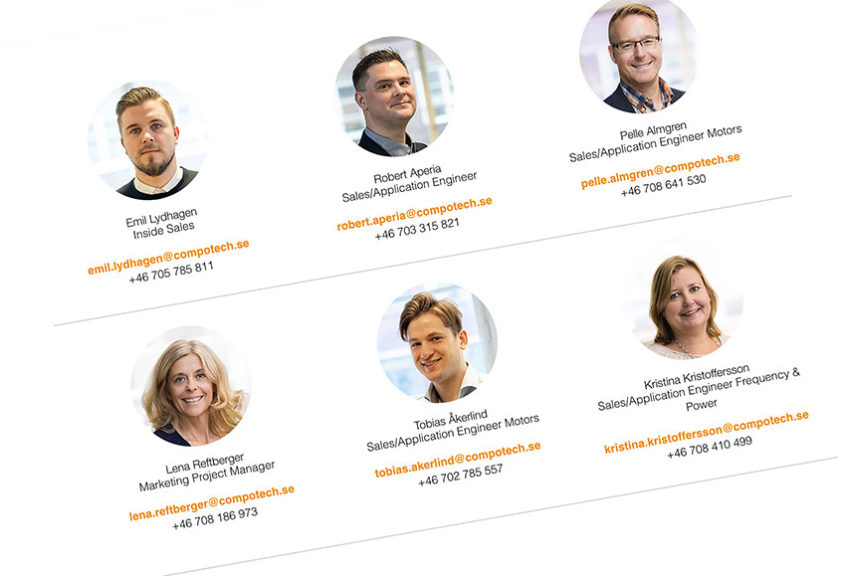

A few months ago, we expanded Compotech into the Benelux region, we did also present our new CEO about the same time. Now we´re expanding our comprehensive quality work!

We already have an established quality organisation working on-site in Asia, and now we are strengthening our headquarters with an experienced quality manager. Rashin Kabiri has, among other things, been responsible for quality assurance at Ericsson and Sony Ericsson, and she holds a master’s degree in Mathematical Statistics from Stockholm University. This recruitment gives us unique skills to further develop our suppliers and ourselves. Rashin will focus on collaborating with customers and suppliers through proactive quality activities.

Welcome to Compotech, Rashin! Briefly tell us about your experiences from previous workplaces.

– I worked at Sony Ericsson for four years. It was a great place to work at, learning their high demands on quality, both externally and internally. My first position was as a Supplier Quality Engineer, before I became an Industrialization Project Quality Manager. I learned about the importance of having clearly defined processes and traceability in production and the daily work, says Rashin. After Sony Ericsson, I moved on to Ericsson, where I worked for seven years as a Verification and Quality Leader.

What will you contribute at Compotech?

– Having a good and open communication with our suppliers is truly important, in order to convey customers’ and Compotech’s quality requirements. I’m responsible for increasing the quality awareness. Through our supplier development program, we aim to bring about a higher level of process control and a better understanding of what is important for our customers. The customer’s benefit will be better and more robust products, more reliable delivery times, and improved control over the entire supply chain. These are the things that have become more and more important now when we no longer only sell components, but also develop complex solutions for our customers.

Our project model includes quality activities right from the feasibility study phase. Can you tell us more about it?

– I’m part of the engineering team here at Compotech, that are responsible for developing complex solutions. I am involved from the project start and work with the team and the customer, going through the specification. Our project model helps us to understand customer requirements and how to involve all necessary resources, both internally at the customer and externally through us, to be more efficient and to reduce lead times. This is a way of working I am used with from Ericsson and Sony Ericsson, so I know that it is a proven and effective method.

Last but not least, why did you choose to come work for us?

– I found it very exciting that quality and processes are something that permeates our entire way of working here. And I look forward to develop our processes even more and take the company to the next level, says Rashin.

Rashin is also a part of Compotech’s quality team, working on-site from Stockholm as well as Shenzhen and Shanghai. Together they carry out regular on-site audits at suppliers and sometime even accompanied by customers.

Rashin Kabiri started her position at Compotech February 1, 2017.

Motion Control for decentralised intelligence with EtherCAT from FAULHABER

Decentralised intelligence and the capacity for real-time communication with higher level process control technology and flexibility in usage applications are requirements for cutting-edge drive systems within the context of networked industry (cf. company box) has taken appropriate action and developed a new generation of motion controllers.

Galil Now Provides Support for Linux

Support for Galil’s latest generation software has now been expanded to include Linux operating systems.

Read more

We welcome Michael Ullskog as our new CEO

After 16 years as CEO of Compotech Jan Eriksson has decided to hand over the reins to Michael Ullskog, recruited from the same position at our sister company RECAB. Read more

Compotech expands to the Benelux!

The Compotech Benelux sales office is strategic located in The Hague. Read more