Normal delivery capacity and operation during Corona pandemic

During these peculiar times, we continue to develop everything from simple solutions to pioneering advances for optimum levels of engineering precision and efficiency.

We´re keen on taking part of solving the challenges you may face in your industrial application.

Deliveries

Presently regular lead times apply on deliveries. We have not been affected by interference in the form of delivery problems to any significant extent. However, we may need to adjust delivery times and/or deliver partial orders in the event of any possible factory impact.

Compact, highly reliable pushbuttons and Emergency Stop buttons

NEW pushbuttons and illuminated pushbuttons for 16.2 mm mounting holes are especially suitable for handheld control devices, or any application that requires robust switch functions in a low profile. They are very compact and provide distinct haptic feedback. Read more

Video guide: New features in script language for motion controllers from FAULHABER

FAULHABER’S motion controller provides a simple solution to quickly let you realise your dynamic design ideas

This is particularly important in today’s world as the demands for decentralized electronics and capacity to handle complex real-time applications become ever higher.

Of course, both motor and motion controller can do significantly more than is shown here. For a more comprehensive instruction of how to program in BASIC for automation purposes, use the whitepaper from FAULHABER concerning its local scripting capabilities (pdf).

Interested in downloading the ‘Motion Manager’ software and try out the motion controller while connected to a motor? We guide you all the way in below videotutorial.

Want to know more? Ask us and we’ll be happy to help!

LedgeCircle – 35 mm innovation that lights the way

Well thought-out lighting and a fresh appearance from the moment you step into the office was the idea behind the LedgeCircle ceiling range from the technology company DEFA. With a thickness of 35 mm – and world-class control options – the company itself points out that you can obtain a fresh and lightweight luminaire which is suitable for both walls and ceilings. Read more

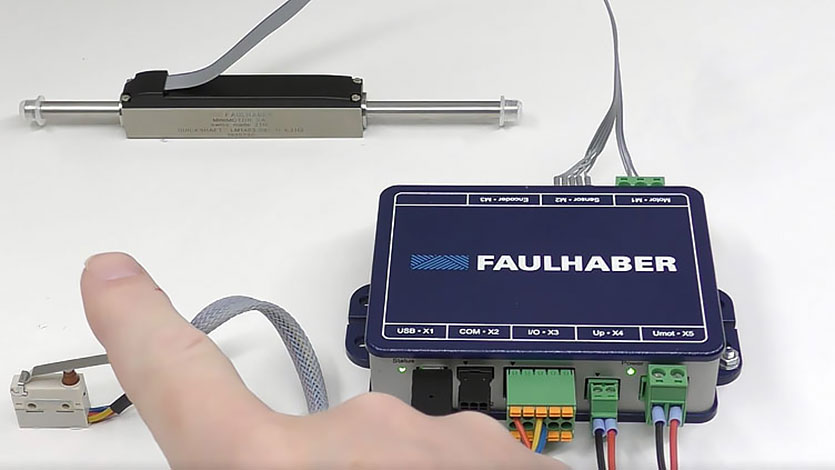

Video guide: Connect your motion controller and motor!

The motion controllers from FAULHABER are not only powerful – the MC-series are easy to handle. But since you probably have more important things to do than to only read manuals, we’ve put together a simple guide in video format. In just 7.5 minutes, you will learn to connect the FAULHABER’s 3268 … BX4 brushless motor to the FAULHABER MC5010 motion controller.

We guide you all the way from downloading the free software, to writing and running a simple program that demonstrates a few different types of motion. Of course, both motor and motion controller can do significantly more than we show here.

Want to know more? Ask us and we’ll be happy to tell you more!

Intelligent light control to minimise waste

Fifty per cent. Pick a company at random and there is a high risk that much of their electricity consumption on lighting is wasted. Lamps are on even though nobody is there. The ‘last one out turns off the lights’ approach is a principle that has never worked anywhere. Read more

Scientist explains motor technology

The technology behind RoboDrive was originally designed for use in the space and for a number of years it has been used in a robot outside the ISS space station. In this video Manfred Schedl explains how the engine technology works as he originated and performed during his time at the German Aerospace Center (DLR).

RoboDrive multi-pole high torque motors for maximum torque and high precision – at the lowest possible weight and power loss. The motors are ideal for industries such as medical, aerospace, robotics and automation.

The application examples can provide guidance on how to benefit from RoboDrive. But there are of course more applications, or what do you think?

Contact me if you want to know more!

Say Hello to Our New Quality Manager from Ericsson!

A few months ago, we expanded Compotech into the Benelux region, we did also present our new CEO about the same time. Now we´re expanding our comprehensive quality work!

We already have an established quality organisation working on-site in Asia, and now we are strengthening our headquarters with an experienced quality manager. Rashin Kabiri has, among other things, been responsible for quality assurance at Ericsson and Sony Ericsson, and she holds a master’s degree in Mathematical Statistics from Stockholm University. This recruitment gives us unique skills to further develop our suppliers and ourselves. Rashin will focus on collaborating with customers and suppliers through proactive quality activities.

Welcome to Compotech, Rashin! Briefly tell us about your experiences from previous workplaces.

– I worked at Sony Ericsson for four years. It was a great place to work at, learning their high demands on quality, both externally and internally. My first position was as a Supplier Quality Engineer, before I became an Industrialization Project Quality Manager. I learned about the importance of having clearly defined processes and traceability in production and the daily work, says Rashin. After Sony Ericsson, I moved on to Ericsson, where I worked for seven years as a Verification and Quality Leader.

What will you contribute at Compotech?

– Having a good and open communication with our suppliers is truly important, in order to convey customers’ and Compotech’s quality requirements. I’m responsible for increasing the quality awareness. Through our supplier development program, we aim to bring about a higher level of process control and a better understanding of what is important for our customers. The customer’s benefit will be better and more robust products, more reliable delivery times, and improved control over the entire supply chain. These are the things that have become more and more important now when we no longer only sell components, but also develop complex solutions for our customers.

Our project model includes quality activities right from the feasibility study phase. Can you tell us more about it?

– I’m part of the engineering team here at Compotech, that are responsible for developing complex solutions. I am involved from the project start and work with the team and the customer, going through the specification. Our project model helps us to understand customer requirements and how to involve all necessary resources, both internally at the customer and externally through us, to be more efficient and to reduce lead times. This is a way of working I am used with from Ericsson and Sony Ericsson, so I know that it is a proven and effective method.

Last but not least, why did you choose to come work for us?

– I found it very exciting that quality and processes are something that permeates our entire way of working here. And I look forward to develop our processes even more and take the company to the next level, says Rashin.

Rashin is also a part of Compotech’s quality team, working on-site from Stockholm as well as Shenzhen and Shanghai. Together they carry out regular on-site audits at suppliers and sometime even accompanied by customers.

Rashin Kabiri started her position at Compotech February 1, 2017.

A closer look at the tools in Galil’s new software environment GDK

The Galil Design Kit (GDK) is Galil’s newest software environment that provides easy communication with Galil’s motion controllers and PLCs. Galil has recently introduced the new Scope and Tuner to GDK’s growing list of tools and capabilities. All tools are customizable by editing the XLM that’s located in the “More Options” menu at the top right corner of the GDK software.

GDK now includes the following six tools:

- Scope: emulates a traditional digital Oscilloscope.

- Tuner: assists the user in optimizing their system’s performance.

- Terminal: send commands and receive responses from the controller.

- Editor: write, save, and execute application programs.

- Viewer: enables real-time viewing of the controller’s I/O status, motor position, and more.

- Setup: read, edit, save, and restore all controller memory.